Sharp MX-6500N Adjustment Guide

Sharp MX-6500N Manual

|

View all Sharp MX-6500N manuals

Add to My Manuals

Save this manual to your list of manuals |

Sharp MX-6500N manual content summary:

- Sharp MX-6500N | Adjustment Guide - Page 1

MX-6500N MX-7500N Administrator Machine Adjustment Guide Please keep the manual in a safe place where it will not be lost. - Sharp MX-6500N | Adjustment Guide - Page 2

Caution The Machine Adjustment is provided assuming that an administrative user who has sufficient knowledge for machine maintenance and management and is responsible incidents such as insufficient print quality or product performance, increase in toner consumption and influence on machine life. - Sharp MX-6500N | Adjustment Guide - Page 3

(Forced Execution) ...11 1.3 Fuser Adjustment...11 1.3.1 Fusing Temperature Setting ...11 1.4 Transfer...12 1.4.1 Primary Transfer Current Standard Calibration...15 1.5.4 Copy Calibration by Dither Pattern...15 1.5.5 Printer Calibration by Dither Pattern ...16 1.5.6 Colour Copy Black Component - Sharp MX-6500N | Adjustment Guide - Page 4

is installed) ...26 3.4.1 Punch Position Adjustment...26 3.4.2 Punch Mode Switch...26 3.4.3 Punch Operation Skew Adjustment...26 3.5 Folding Unit ...27 3.5.1 Saddle Fold Position Adjustment ...27 3.5.2 C-Fold Position Adjustment ...27 3.5.3 Accordion Fold Position Adjustment...27 3.5.4 Double Fold - Sharp MX-6500N | Adjustment Guide - Page 5

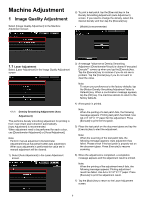

content, procedure and caution on each adjustment so that users in charge of machine maintenance understand and perform the machine or between jobs. Grey balance adjustment Manual adjustment for gradation density This adjustment either MX-LCX3 N or MX-LC12. LCT Large Capacity Trays This refers to - Sharp MX-6500N | Adjustment Guide - Page 6

is performed the value set in manual adjustment will be cleared. 1) Select key to continue if you do not see a problem. Tap the [Cancel] key if you do not want to clear the [OK] key. The machine reboots to return to the factory defaults. 4) A test patch is printed. Note: When the printing - Sharp MX-6500N | Adjustment Guide - Page 7

patch with a densitometer. Note: The densitometer is to be prepared by users. 1) Select [Densitometer Adjustment] in the Laser Adjustment screen. 2) To [OK] key. The machine reboots to return to the factory defaults. 3) A test patch containing 4 columns of 28 patches (3-30) is printed. Note: When - Sharp MX-6500N | Adjustment Guide - Page 8

] key. When a confirmation message appears, tap the [OK] key. The machine reboots to return to the factory defaults. 3) A test patch containing 4 columns of 28 patches (3-30) is printed. Note: When the printing of a test patch fails, the following message appears: Printing test patch has failed - Sharp MX-6500N | Adjustment Guide - Page 9

checked, adjustment result is printed. Input range: [0] to [100] Default: 50 3) Tap the [Back] key to return to Laser Adjustment screen. 1.1.5 Print Skew Adjustment This performs print skew adjustment manually. 1) Select [Print Skew Adjustment] in the Laser Adjustment screen. 2) - Sharp MX-6500N | Adjustment Guide - Page 10

, a completion message appears. 1.1.6.2 Registration Adjustment (Manual) 1) Select [Manual] in the Registration Adjustment screen. 2) Select the the execution frequency of the density adjustment. Input range: [1] to [99] Default: [50] for each Note: When the printing of the adjustment result fails, - Sharp MX-6500N | Adjustment Guide - Page 11

. Input range: [-2] to [2] Default: [0] for each Note: Toner consumption may increase by the settings. values entered manually using Copy Colour Balance Adjustment and Printer Colour Balance Adjustment adjust the temperature high Poor fusing caused by low temperature (toner is not on the paper) - Sharp MX-6500N | Adjustment Guide - Page 12

Fusing Temperature Setting screen 2) Select the colour to adjust and enter the desired value. Input range: [-10] to [10] Default range: [-20] to [20] Default: [0] for each Note: If image problems such as misalignment or streaks occur Value Setting This performs toner transfer adjustment by fine - Sharp MX-6500N | Adjustment Guide - Page 13

tap the [Return Entered Values to Zero] key. Input range: [-30] to [30] Default: [0] for each 3) Tap the [Register] key to register the setting. Note: To reset Quality Adjustment screen. 1.4.3 PTC Current Value Setting This performs toner transfer adjustment by fine tuning PTC current value. When the - Sharp MX-6500N | Adjustment Guide - Page 14

and density point to adjust. Enter the desired value and then tap the [Execute] key. Example of the Printer Colour Balance Adjustment screen The [Set in a Batch] checkbox is not checked by default. When this checkbox is checked, the value [500] appears in the textbox. Note: When the [Set in a Batch - Sharp MX-6500N | Adjustment Guide - Page 15

again, print a print pattern, and check the results of adjustment. Note: To return your preferences to the factory defaults, tap the [Return Printer Colour Balance Adjustment Value to Default.] key. When a confirmation message appears, tap the [OK] key. Your preferences are returned to the factory - Sharp MX-6500N | Adjustment Guide - Page 16

test patch on the document glass. Press [Execute] to start the auto adjustment. Place the test patch in portrait orientation. 9) When the printer calibration by screen is completed, a completion message appears. Note: When the scanning of the test patch fails, the following message appears: Auto - Sharp MX-6500N | Adjustment Guide - Page 17

are returned to the factory defaults and the screen returns to the Image Quality Adjustment screen. 1.5.7 Area Separation Level Adjustment This performs area separation level adjustment. Reproducibility of photos and text when copying or scanning the originals contains both photos and text can - Sharp MX-6500N | Adjustment Guide - Page 18

. Caution: Fuser temperature adjustment stops when you enter the machine adjustment mode. Therefore, the displayed temperature may not correspond with the fusing temperature for printing. 3) To return to the Other Functions screen, tap the [Back] key. 1.6.2 PTC Cleaning This performs PTC cleaning - Sharp MX-6500N | Adjustment Guide - Page 19

[Ratio Adjustment] in the Image Position/Ratio/Area Adjustment screen. Note: To return your preferences to the factory defaults, tap the [Return Scan Ratio Adjustment Value to the Default] key. When a confirmation message appears, tap the [OK] key. Your preferences are returned to the factory - Sharp MX-6500N | Adjustment Guide - Page 20

Print Void Settings] in the Void Area Adjustment screen. 2) Enter the desired values and tap the [Register] key. Input range: [0] to [99] (1 = 0.1 mm) Defaults: Print Lead Edge Void Amount Adjustment: [40] to [99] Print Rear Edge Void Amount Adjustment: [30] to [99] FRONT/REAR Void Amount Adjustment - Sharp MX-6500N | Adjustment Guide - Page 21

: [20] Side 2 rear edge image loss amount: [20] Note: To return your preferences to the factory defaults, tap the [Return Duplex Single Pass Feeder Image Loss Amount Settings to the Default] key. When a confirmation message appears, tap the [OK] key. Your preferences are returned to the factory - Sharp MX-6500N | Adjustment Guide - Page 22

4, LCT Bypass Tray and LCC are displayed only when the options are installed. To return your preferences to the factory defaults, tap the [Return Print Off-Centre Adjustment Value to Default] key. When a confirmation message appears, tap the [OK] key. Your preferences are returned to the factory - Sharp MX-6500N | Adjustment Guide - Page 23

saddle finisher, trimming module, finisher, punch module, and folding unit can be adjusted: The installed options are displayed as follows: One staple: [70]-[130] Two staples: [85]-[115] (1 = 0.1 mm) Default: 100 for each Note: Staple position in paper feed direction cannot be adjusted. Functional - Sharp MX-6500N | Adjustment Guide - Page 24

saddle folding. The 10-key pad appears when the textbox is tapped. Enter the desired value. Input range: [42] to [58] (1 = 0.25 mm) Default: [50] for each 3.1.4 Fold/Staple Position Adjustment for Saddle Stitch This performs adjustment of fold and staple positions for saddle stitch (fold and staple - Sharp MX-6500N | Adjustment Guide - Page 25

] (1 = 0.1 mm) Two staples: [85]-[115] (1 = 0.1 mm) Default: [100] for each Note: Staple position in paper feed direction cannot be adjusted. as the following table shows: Input range: [50] to [150] (1 = 0.1 mm) Default: [100] for each Paper size A4R/Letter R or smaller Larger than A4R/Letter R 25 - Sharp MX-6500N | Adjustment Guide - Page 26

to the lead edge and in the direction of paper width. The 10-key pad appears when the textbox is tapped. Enter the desired value. Default: [High Production Mode] Note: Select [High Accuracy Mode] when punch hole is skewed against paper. 3) Tap the [Register] key to switch to the desired mode - Sharp MX-6500N | Adjustment Guide - Page 27

Enter the desired values. Diagram showing the saddle fold position Input range: [80] to [120] (1 = 0.1 mm) Default: [100] for each 3.5 Folding Unit Select [Folding Unit] in the Peripheral Adjustment screen. 3.5.1 Saddle Fold Position Adjustment This performs adjustment of fold position for saddle - Sharp MX-6500N | Adjustment Guide - Page 28

screen. 2) Adjust the double fold position for when the folding unit is installed. The 10-key pad appears when each of the textboxes is tapped. Enter the desired values. Input range: [46]-[53] The default is [50]. Diagram showing the Z-fold position Input range: A4R/Letter R (8 1/2 x 11R): [46 - Sharp MX-6500N | Adjustment Guide - Page 29

is tapped just after the numerical display is cleared, the entry is cancelled and not reflected in the textbox; the original value or the factory default value remains effective. The [Cancel] and [Back] keys in each setting screen are active while the 10-key pad is being displayed. When the - Sharp MX-6500N | Adjustment Guide - Page 30

ADJ-EX-2

MX-6500N

MX-7500N

Administrator Machine

Adjustment Guide

Please keep the manual in a safe place where it will not be lost.