Lexmark E260dn Service Manual - Page 66

Service error codes

|

View all Lexmark E260dn manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 66 highlights

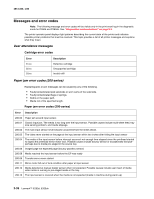

4513-220, -230 Service error codes Service error codes are generally non-recoverable except in an intermittent condition when the printer can be put into POR to temporarily recover from the error condition. Service error codes (9xx) Error Description Engine software service errors 902.xx Engine software error DC pick motor errors 914.00 DC pick motor error 914.01 Lost encoder feedback Transfer service errors 917.00 Transfer service error 917.01 Transfer servo result too low. 917.02 Immediate transfer servo indicates that the HVPS requires erase lamps. Fuser service errors 920.00 Under temperature during steady state control. 920.01 Fuser took too long to heat up after transitioning to new enhanced mode. 920.02 Fuser fell too far below desired temperature while printing. 920.03 Fuser too cool while checking for slope change. 920.04 Fuser too cool when heating to desired temperature after slope change. 920.05 Fuser under temperature while printing 920.06 Fuser under temperature while printing 920.07 Fuser under temperature while printing 920.08 Fuser temperature did not increase after IR recovery. 920.20 Belt fuser under temperature during steady state control. This can occur in printing or standby modes. 921.00 Under temperature during standby control. 921.01 Fuser temperature did not reach standby temperature after two attempts 922.00 Fuser failed to ramp to target temperature 922.01 Fuser did not reach standby temperature in time (standby control) 922.02 Hot roll took too long to reach the beginning lamp detection temperature. 922.03 Hot roll reached final lamp detection temperature, but took longer than largest time in lookup table. 922.04 Hot roll timed out in trying to reach the final lamp detection temperature. 922.05 Did not roll over to a steady state control in time after the hot roll lamp detection. 922.06 Hot roll did not reach the operating temperature in time (new enhanced control). 2-40 Lexmark™ E260d, E260dn