Stihl MS 311 User Manual - Page 21

Chain Brake, Checking Operation, Brake Band - operating manual

|

View all Stihl MS 311 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 21 highlights

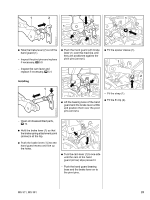

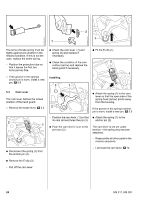

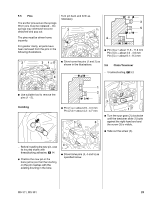

5. Chain Brake 5.1 Checking Operation 5.2 Brake Band 4903RA018 TG The chain brake is one of the most important safety devices on the machine. Its efficiency is measured in terms of the chain braking time, i.e. the time that elapses between activating the brake and the saw chain coming to a complete standstill. - Remove the clutch drum, b 4.1 - Troubleshooting, b 3.2 1 4903RA016 TG Contamination (with chain oil, chips, fine particles of abrasion, etc.) and smoothing of the friction surfaces of the brake band and clutch drum impair the coefficient of friction, which prolongs the braking time. A fatigued or stretched brake spring has the same negative effect. - Starting the engine : Pull off the bumper strip (1). 1 - Engage the chain brake. The brake band is now tensioned. : Remove the screw (1) from the underside of the machine. - With the chain brake activated (locked), open the 1 1 throttle wide for a brief period (max. 3 seconds) - the chain must not rotate. 4903RA019 TG - With the chain brake released, open the throttle wide and activate the brake manually - the chain must come to an abrupt stop. The braking time is in order if deceleration of the saw chain (less than a second) is imperceptible to the eye. : Take out the screws (arrows). - Remove the cover (1). If the chain brake does not operate properly, refer to troubleshooting, b 3.2. 4903RA017 TG : Pry the brake band (1) out of its seat (arrow). - Remove the brake band (1). Do not overstretch the brake band. - Pull the hand guard towards the handlebar to simplify assembly of the brake band. 20 MS 311, MS 391