Stihl MS 311 User Manual - Page 36

Bearings / Crankshaft

|

View all Stihl MS 311 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 36 highlights

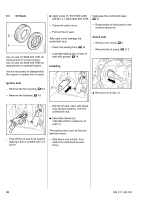

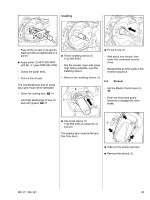

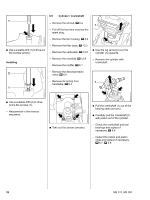

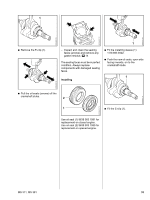

1 1 4903RA085 TG 4903RA083 TG 4903RA072 TG : Fit the screws (arrows). : Tighten down the screws (arrows) in an alternate pattern. : Pull the ball bearing (1) off the straight crankshaft stub. - Reassemble all other parts in the reverse sequence. 2 - Heat the bearing inner race to about 150°C (300°F). : Push the ball bearing onto the straight crankshaft stub as far as stop. 6.6 Bearings / Crankshaft 1 4903RA084 TG - Remove the cylinder, b 6.5 1 - Remove the crankshaft and pull off the oil seals, b 6.5 : The crankshaft (1), connecting - Remove the piston, b 6.7 rod (2) and needle bearing form an inseparable unit. 4903RA086 TG 1 : Pull the ball bearing (1) off the tapered crankshaft stub. 4903RA082 TG When fitting a replacement crankshaft, always install new ball bearings and oil seals. Before installing, clean the crankshaft, b 14 Heated ball bearings must be installed quickly because the crankshaft stubs absorb heat and expand. - Heat the bearing inner race to about 150°C (300°F). : Push the ball bearing onto the tapered crankshaft stub as far as stop. - Lubricate the needle bearing with oil. - Install the piston, b 6.7 - Install the crankshaft and oil seals, b 6.5 MS 311, MS 391 35