Stihl MS 311 User Manual - Page 26

Installing, Chain Tensioner

|

View all Stihl MS 311 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 26 highlights

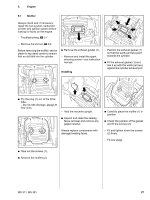

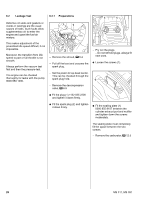

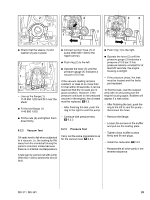

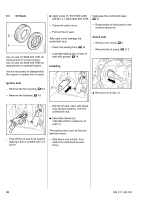

5.5 Pins The anchor pins secure the springs. Worn pins must be replaced - the springs may otherwise become detached and pop out. The pins must be driven home squarely. For greater clarity, all parts have been removed from the pins in the following illustrations. 2 3 15 Turn pin back and forth as necessary. 2 1 4903RA046 TG : Drive home the pins (1 and 2) as shown in the illustrations. a 3 5 c 4 b : Pin (3) a = about 11.6 - 11.8 mm Pin (4) b = about 4.6 - 4.8 mm Pin (5) c = about 9.1 - 9.3 mm 5.6 Chain Tensioner 4903RA049 TG - Troubleshooting, b 3.2 4 a 4903RA044 TG 4903RA050 TG : Use suitable tool to remove the pins (1 - 5). Installing 1 2 b : Pin (1) a = about 2.9 - 3.3 mm Pin (2) b = about 4.3 - 4.7 mm 3 5 4903RA047 TG 2 3 1 : Turn the spur gear (2) clockwise until the tensioner slide (1) butts against the right-hand end and the screw (3) is visible. : Take out the screw (3). 4903RA045 TG 4903RA048 TG - Before installing the new pin, coat its knurled shank with threadlocking adhesive, b 14 : Position the new pin in the bore (arrow) so that the knurling on the pin meshes with the existing knurling in the bore. 4 : Drive home pins (3, 4 and 5) as specified below. MS 311, MS 391 25