Stihl MS 311 User Manual - Page 35

Inspect and clean the sealing

|

View all Stihl MS 311 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 35 highlights

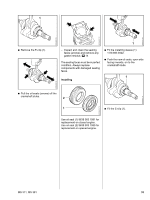

1 533RA104 TG 4903RA076 TG 4903RA078 TG - Lubricate the piston, piston rings and cylinder wall with oil. : Position the piston rings so that the radii at the ring gap meet at the fixing pin in the piston groove (arrows) - there is otherwise a risk of ring breakage. When properly aligned, the piston rings are compressed by the cylinder's taper. : Carefully push the piston with crankshaft (1) into the cylinder. 1 - Inspect and clean the sealing face on the engine housing and remove any gasket residue, b 14 The sealing faces must be in perfect condition. Always replace components with damaged sealing faces. : Apply sealant to the groove in the sealing face, b 14 4903RA075 TG 4903RA090 TG 4903RA079 TG - Line up the piston with crankshaft before fitting them in the cylinder. Viewed from the exhaust port (arrow), the long crankshaft stub (1) must be on the right. - Place the crankshaft with bearings and oil seals in the bearing seats, making sure the oil seals are firmly against their stops (arrows) in the cylinder. 2 1 - Hold the crankshaft (1) steady. : Fit the cylinder (2) with crankshaft (1) in the engine housing. 34 MS 311, MS 391