Brother International LK3-B432E MKII Instruction Manual - English - Page 45

Adjusting the needle up stop position, 10-13. Adjusting the thread wiper

|

View all Brother International LK3-B432E MKII manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 45 highlights

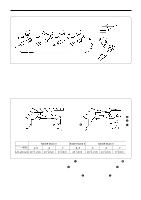

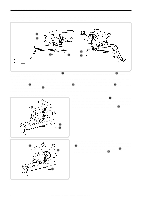

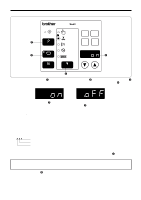

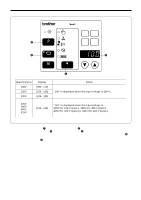

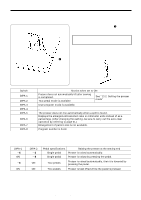

10 . STANDARD ADJUSTMENTS 10-12. Adjusting the needle up stop position The needle up stop position is adjusted so that the index mark w on the machine pulley q is inside the mark r on the belt cover e. If adjustment is necessary, loosen the screw t at the "U" mark of the machine pulley q and adjust the po- sition of the machine pulley q. The machine pulley q e stops later if it is turned clockwise, and it stops earlier if it is turned counterclockwise. NOTE: r The screw y at the "D" mark is an adjusting screw for the needle down detection function and is adjusted to match q the feed timing, so it should not be loosened. The screw u is a screw for detecting the machine stop position, and should not be loosened. w t * If the index mark w is not inside the mark r when y u the sewing machine is started, error code "E-50" will be displayed. Turn the machine pulley to move the index mark w to the correct position and then start the sewing machine. 10-13. Adjusting the thread wiper q 2±0.5mm we r t Approx. 20mm 1. Loosen the set screw w and move the wiper arm support e up or down to adjust so that the clearance between the top of the thread wiper and the needle point q is 2 ± 0.5 mm when the thread wiper is aligned with the center of the needle. * Before carrying out this adjustment, check that the needle bar is lowered 5 to 5.5 mm from the needle up stop position when the sewing machine stops. 2. Loosen the screw r and move the thread guide connecting plate t up or down so that the thread wiper is approximately 20 mm from the needle when it is at the standby position. 39 LK3-B430E-, B431E-, B432E-, B433E- Mark II