Brother International MD-817 Service Manual - Page 18

Adjustment

|

View all Brother International MD-817 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 18 highlights

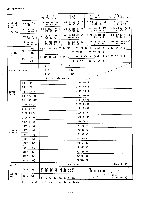

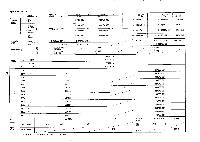

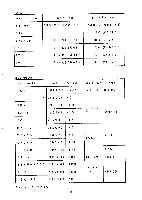

ADJUSTMENT :; M DC Servomotor Rotating direction of machine O About 13mm * Lower the machine head and then mount the belt on the motor pulley and the ma- chine pulley. * The belt fits the machine pulley and the motor pulley as shipped. However, the belt tension may loosen in time; check the belt tension. 0 * The machine rotates counterclockwise as seen from the pulley side. * Adjust the belt 0 by loosening the set screw and turning the nut so that it gives about 13mm when pressed by hand. 2 Needle _position detector (synchronizer) Model DB2-B798 * Take off the synchronizer cover for adjustment. The synchronizer detects the needle with two sensors and controls the needle down signal and the thread trimming signal with one sensor. Needle down stop position 18-22mm 4 Needle up stop position For medium materials 9-11mm For thick materials 10-12mm ce) Model B798 5mm 22-26mm 7.5mm 11-14mm 0 * When adjusting each sensor, do not fail to turn off the power switch. Position adjustment for needle down signal 0. * Turn the machine pulley and set the needle 5mm up from the bottom to align the lower end of the magnet 0 with the upper end of the thread trimming needle down sensor (As for the model 8747 • B748, adjust the needle 7mm up from the bottom and as for the model B798, 7.5mm.) When the lower end of the magnet does not coincide with the upper end of the thread trimming needle down sensor 0, loosen the screw 0 and move the thread trimming needle down sensor for adjustment. When the thread trimming needle down sensor O is moved in the rotating direction, the needle bar comes up. And when in the reverse direction, the needle bar comes down. Turn on the power switch and stop the machine at the needle down stop position so that the distance between the top of the needle plate and the lower end of the needle clamp screw is 18 22mm. (As for the model 8798, the distance is 22 - 26mm.) Position adjustment for needle up signal * Stop the machine at the needle up stop position. The needle point stops 9 - 11mm away from the top of the needle plate for thin and medium materials, and 10 - 12mm for thick materials. (As for the model B798, the needle point stops 11 - 14mm away.) When the needle point does not stop properly, loosen the screw 0 and move the needle up stop sensor 0 for adjustment. When the needle up stop sensor 0 is moved in the rotating direction, the needle bar comes down. And when in the reverse direction, the needle bar comes up. * Tighten the screws 0 and 0 to a torque of 6 - 10kg-cm. - 14 -