Brother International MD-817 Service Manual - Page 50

Brother International MD-817 Manual

|

View all Brother International MD-817 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 50 highlights

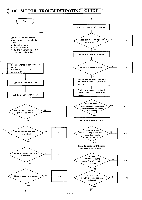

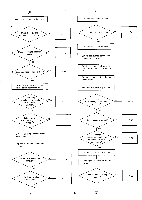

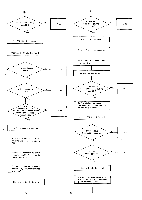

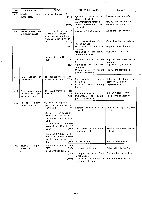

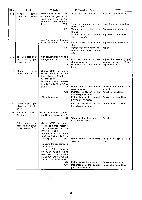

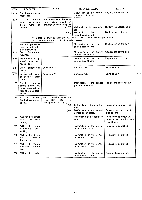

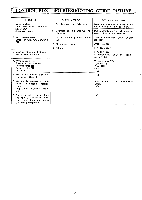

ITEM PROBLEM #8 Needle (lower) doesn't stop. #9 Needle (lower) stops at different places. CHECK PROBABLE CAUSE REMEDY • Is the synchronizer OK? (NO) (YES) Synchronizer installation position is not suitable. Synchronizer malfunction. Control printed-circuit board malfunction. Position adjustment: 0.5mm Replace the synchronizer. Replace the control box. • Is the V-belt loose? (YES) • Is there oil, grease, dirt scratches, etc. on the syn- chronizer's reflecting sur- face? (YES) (NO) • Is the motor's braking noise loud? (YES) (NO) Insufficient V-belt tension. Dirt of the synchronizer's reflecting surface. Malfunction of the synchronizer. Malfunction of the control printed-circuit board. Reduced motor braking force. Malfunction of the synchronizer. Malfunction of the control printed-circuit board. Adjust the V-belt tension. Clean the reflecting surface. Replace the synchronizer. Replace the control box. Replace the motor brake clearance. Replace the synchronizer. Replace the control box. #10 Poor position of • Is adjustment at syn- needle stop. chronizer possible? (YES) Poor position of needle Adjust needle (lower) stop (lower) stop. between 18 - 22mm. (NO) Reduced motor braking Replace the motor. force. #11 After treadle return, • Is thread trimming speed machine won't oper- suitable? (NO) Low speed is too fast. Adjust VR TRIM (LOW). ate at low speed. (YES) Malfunction of control Replace the control box. printed-circuit board. #12 Thread trimmer • Is the 1-pin plug (of the 12 doesn't function. pins) in the control box connected? (NO) Improper connection of the Connect the 1-pin plug cor- 1-pin plug. rectly. • Switch OFF the power and measure the resistance of the thread trimmer sole- noid. Is there about 7ohms be- tween 0 and 0 of the 12 pins? (NO) Malfunction of the thread Replace the thread trimmer trimmer solenoid. solenoid. • Does the 8A fuse (at the top of the control printed- circuit board) appear nor- mal? (NO) 8A fuse failure. Replace the 8A fuse. #13 Needle (upper) • Is the speed at low speed doesn't stop. OK? (NO) Low speed is too fast. Adjust VR TRIM (LOW). • Is the synchronizer OK? (NO) Improper installation of the Replace the synchronizer. synchronizer. (YES) Malfunction of the control Replace the control box. printed-circuit board. - 46 -