Brother International MD-817 Service Manual - Page 51

Brother International MD-817 Manual

|

View all Brother International MD-817 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 51 highlights

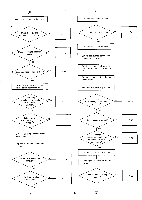

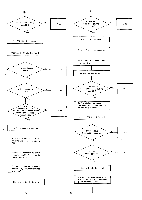

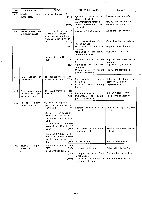

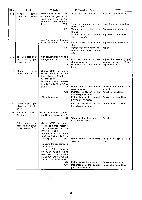

ITEM PROBLEM #14 Needle (upper) stops at different places. #15 The stop position of the needle (upper) is not correct. #16 Thread wiper doesn't function. #17 Thread wiper operation time is too short. #18 Reverser doesn't function. (when treadle is depressed and actuator is switched ON) CHECK PROBABLE CAUSE • Is the V-belt loose? (YES) • Is there oil, grease, dirt scratches, etc. on the syn- chronizer's reflecting sur- face? (YES) (NO) • Are the speed and torque at low speed OK? (NO) (YES) Insufficient V-belt tension. Dirt of the synchronizer's reflecting surface. Malfunction of the synchronizer. Malfunction of the control printed-circuit board. Speed at low speed is too slow. Operational malfunction related to head thread trimming. • Can adjustment be made at the synchronizer? (YES) (NO) Improper needle (upper) stopping position. Reduction of motor brake force. • Switch OFF the power switch and then measure the resistance of the thread wiper solenoid. • Is there 5ohms between 0 pins and 0 of the 12-pin plug? (NO) (YES) • Other than above. Malfunction of the thread wiper solenoid. Improper installation of the thread wiper solenoid. Malfunction of the control printed-circuit board. Improper installation of the thread wiper solenoid. • Can the reverser be operated by the reverse lever? (NO) • Switch OFF the power switch and then measure the resistance of the reverse solenoid. • Is there about 7ohms be- tween pins Co and e of the 12-pin plug? (YES) • Measure the resistance of the actuator. Is there 0ohms between pins 0 and 0 of the 12-pin plug with the actuator switch ON, and cohms with the actuator switch OFF? (NO) (YES) Operational malfunction related to head reverse. Malfunction of the reverse solenoid. Malfunction of the actuator. Malfunction of the control printed-circuit board. REMEDY Adjust the V-belt tension. Clean the reflecting surface. Replace the synchronizer. Replace the control box. Adjust the VR TRIM (LOW). Adjust. Adjust the needle (upper) stop position by 10 - 12mm. Replace the motor. Replace the thread wiper solenoid. Adjust the installation. Replace the control box. Correct the installation. Adjust. Replace the reverse solenoid. Replace the actuator. Replace the control box. - 47 -