Brother International MD-817 Service Manual - Page 54

Control, Troubleshooting, Guide, Outline

|

View all Brother International MD-817 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 54 highlights

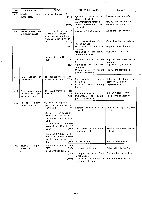

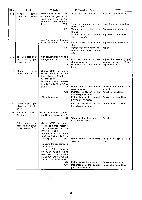

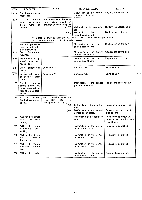

CONTROL BOX TROUBLESHOOTING GUIDE OUTLINE PROBLEM 1. Motor won't operate. Lamp does not illuminate when power is ON. (Fuse has blown.) 2. Motor won't operate. Lamp illuminates when power is ON. 3. Machine abnormal high-speed rotation when power is ON. 4. When power is ON: Thread trimmer continues. Reverse continues. Brake remains ON. All continue. 5. With treadle forward, excessive high speed; will not stop. 6. With treadle depressed to maximum, high-speed rotation changes. (High-speed rotational irregularity) 7. During speed reduction from high speed, brake doesn't function, or great deviation of needle (lower) stopping position. CHECK METHOD (1) Fuse is replaced and fails again. (2) Operation possible after fuse replacement. (1) LED flashes during forward backtack. (2) Motor roars or hums. (3) Others REPLACEMENT PART D printed-circuit board PTR, D (If PTR is broken then motor frame assembly.) Due to operation of overvoltage protection circuit; no abnormal condition. Treadle printed-circuit board tantalum C1, HIC5 CPU, brake TR 1 HIC1, HIC2, HIC6 HIC4, HIC5, HIC6 D printed-circuit board PTR (singlephase 110V) Thread trimmer TR2 Reverse TR5 Brake TR1 CPU HIC2 HIC6 Poor soldering of treadle printed-circuit board. HIC6 HIC3 - 50 -