Epson Stylus Pro 7600 - UltraChrome Ink Service Manual - Page 211

Cautions, Adjustment Tools

|

View all Epson Stylus Pro 7600 - UltraChrome Ink manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 211 highlights

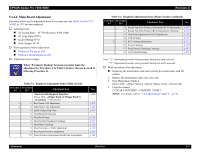

EPSON Stylus Pro 7600/9600 Revision A 5.1 Overview This section describes the adjustment procedures necessary after replacing certain parts and explains how to perform those adjustment procedures. 5.1.1 Cautions Before beginning the adjustment operation, be sure to confirm the following caution items. C A U T IO N „ If you are carrying out adjustments, see "5.1.4 Adjustment Items" (p.212) and then confirm the relevant adjustment items and adjustment procedures. „ When carrying out adjustments, check the cautions displayed in the explanation for each adjustment item thoroughly. If the operation is performed wrong, it could hinder the product's operation or functions. 5.1.2 Adjustment Tools CHECK P O IN T In adjustments and test printing, use Doubleweight Matte Paper roll, unless otherwise specified. Table below lists the tools necessary for adjustments of Stylus Pro 7600/9600. Name Tension Gauge #F770 Thickness gauge Coupling tightening jig Table 5-1. Adjustment Tools Part Code Notes 1060744 / standard tool 2.2kgf ± 220g acceptable (PF Belt tension) Commercially available Thickness: 0.3 / 0.4 / 0.8 / 0.9 mm Tightening force: 3kgf + 500g Table 5-1. Adjustment Tools (continued) Name Part Code Notes 24/44-inch Width Roll Paper Epson or commercially available paper (Doubleweight Matte Paper roll) • MCSP24R4 (24-inch width) • MCSP44R4 (44-inch width) For printer mechanism adjustments and test printing. A3Tracing Paper #F751 1057723 Used for adjustment of the paper status detection sensor (P_REAR) level adjustment. Microtrace #300 LMB, made by Kimoto A3 Copy Paper (PPC) Commercially available product (Example: Fuji Xerox Bright Recycled) Used for adjustment of the paper status detection sensor (P_EDGE) level adjustment. Scale 1000mm #F713 1047746 / A commercially available scale can be purchased. Length:1000mm Scale Stopper #F714 1047745 / A commercially available scale can be purchased. Used in combination with the #F713 (measurements in 0.1 mm units) CR ENC sensor positioning jig 1212926 #F799 Cutter Positioning Jig #F800 1212928 PF ENC sensor positioning tool 1212925 #F798 Ink Cartridge (x7)* Spare Draining cartridge* Use at black ink type change Maintenance Tank* Spare Note "*": Use at adjustments which require test printing. Adjustment Overview 211