Epson Stylus Pro 7600 - UltraChrome Ink Service Manual - Page 263

Mechanism Adjustment

|

View all Epson Stylus Pro 7600 - UltraChrome Ink manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 263 highlights

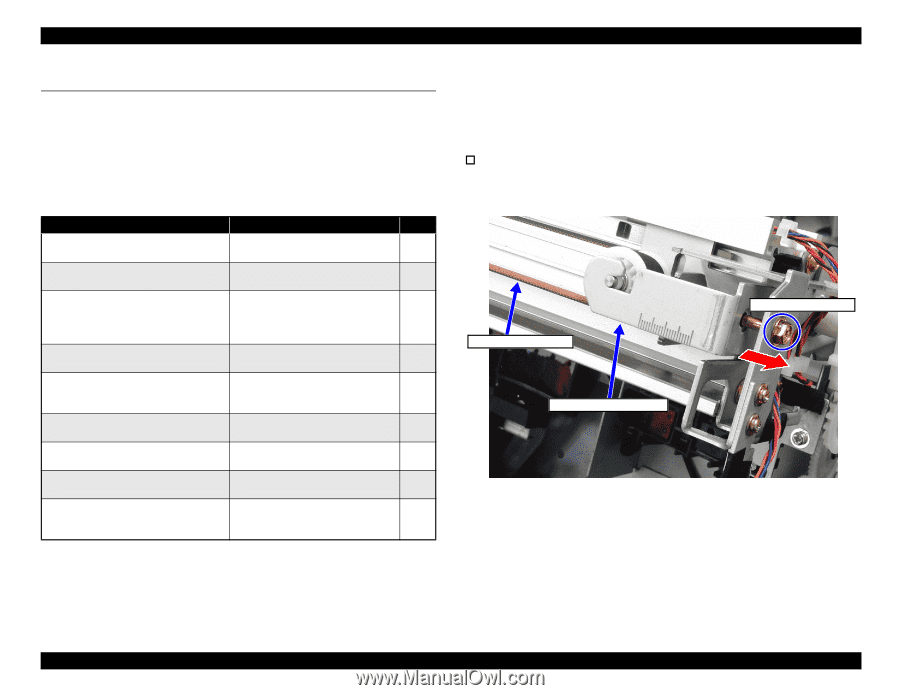

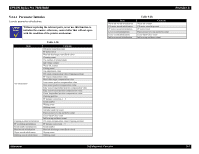

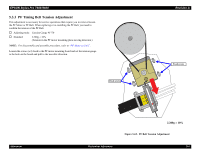

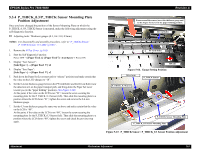

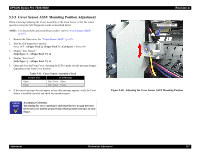

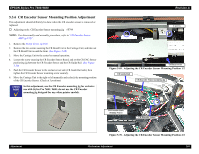

EPSON Stylus Pro 7600/9600 5.3 Mechanism Adjustment 5.3.1 Overview This section describes the mechanism adjustments you need to perform when mechanical parts have been replaced or removed. The relationship between parts and required adjustments are as follows. Table 5-29. Required Mechanism Adjustments Item Description See CR Timing Belt Tension Adjustment At reinstallation of the CR Timing Belt, adjust its tension as specified. p. 263 PF Timing Belt Tension Adjustment At reinstallation of the PF Timing Belt, adjust its tension as specified. p. 264 P_THICK_0.3/P_THICK Sensor Mounting Plate Position Adjustment At reinstallation of the P_THICK sensor or P_THICK_0.3 sensor, make adjustment for paper thickness detection. p. 265 Cover Sensor ASSY Mounting Position Adjustment Adjust the mounting position of the Cover Sensor. p. 267 CR Encoder Sensor Mounting Position Adjustment Adjust the CR Encoder mounting position on the CR Unit, using the dedicated tool. p. 268 Cutter Positioning Adjustment Adjust the cutter position, using the dedicated tool. p. 269 Paper Cutting Position Check Check the result of the adjustment made above. p. 271 Paper Cutting Position Check Adjust the PF Encoder position, using the dedicated tool. p. 272 Head Slant Adjustment (Mechanical Adjustment) Adjust the Print Head slant using the self-diagnostic mode and by mechanical adjustment. p. 247 Revision A 5.3.2 CR Timing Belt Tension Adjustment This adjustment is necessary for service operations that require you to remove/loosen the CR Motor or CR Steel Belt. When replacing or re-installing the CR Steel Belt, you need to confirm the tension of the CR Steel Belt. Tighten or loosen the screws on the Driven Pulley to increase or decrease the tension. † No special tools are required. NOTE: For details, refer to "CR Motor ASSY (p.180)". CR Timing Belt CR Tension Bracket CR Tension Screw Figure 5-64. CR Timing Belt Tension Adjustment Adjustment Mechanism Adjustment 263