Kyocera FS 1020D FS-1020D Operation Guide Rev 1.4 - Page 53

Special Paper, 4.3.1 Transparency (overhead projection film)

|

View all Kyocera FS 1020D manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 53 highlights

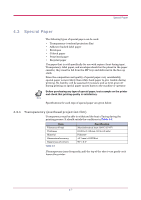

Special Paper 4.3 Special Paper The following types of special paper can be used: • Transparency (overhead projection film) • Adhesive-backed label paper • Envelopes • Colored paper • Preprinted paper • Recycled paper Use paper that is sold specifically for use with copiers (heat-fusing type). Transparency, label paper, and envelopes should not be placed in the paper cassette; they must be fed from the MP tray and delivered in the face up stack. Since the composition and quality of special paper vary considerably, special paper is more likely than white bond paper to give trouble during printing. No liability will be assumed if moisture and so forth given off during printing on special paper causes harm to the machine or operator. Before purchasing any type of special paper, test a sample on the printer and check that printing quality is satisfactory. Note Specifications for each type of special paper are given below. 4.3.1 Transparency (overhead projection film) Transparency must be able to withstand the heat of fusing during the printing process. It should satisfy the conditions in.Table 4-3. Item Tolerance of heat Thickness Material Dimensional accuracy Squareness of corners Table 4-3 Specification Must tolerate at least 190°C (374°F) 0.100 to 0.110 mm (3.9 to 4.3 mils) Polyester ±0.7 mm (±0.0276 in) 90° ± 0.2° If transparency jams frequently, pull the top of the sheet very gently as it leaves the printer. 4-7