Ricoh Aficio MP 7500 S/P Troubleshooting - Page 35

When You Cannot Make Copies As Wanted

|

View all Ricoh Aficio MP 7500 S/P manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 35 highlights

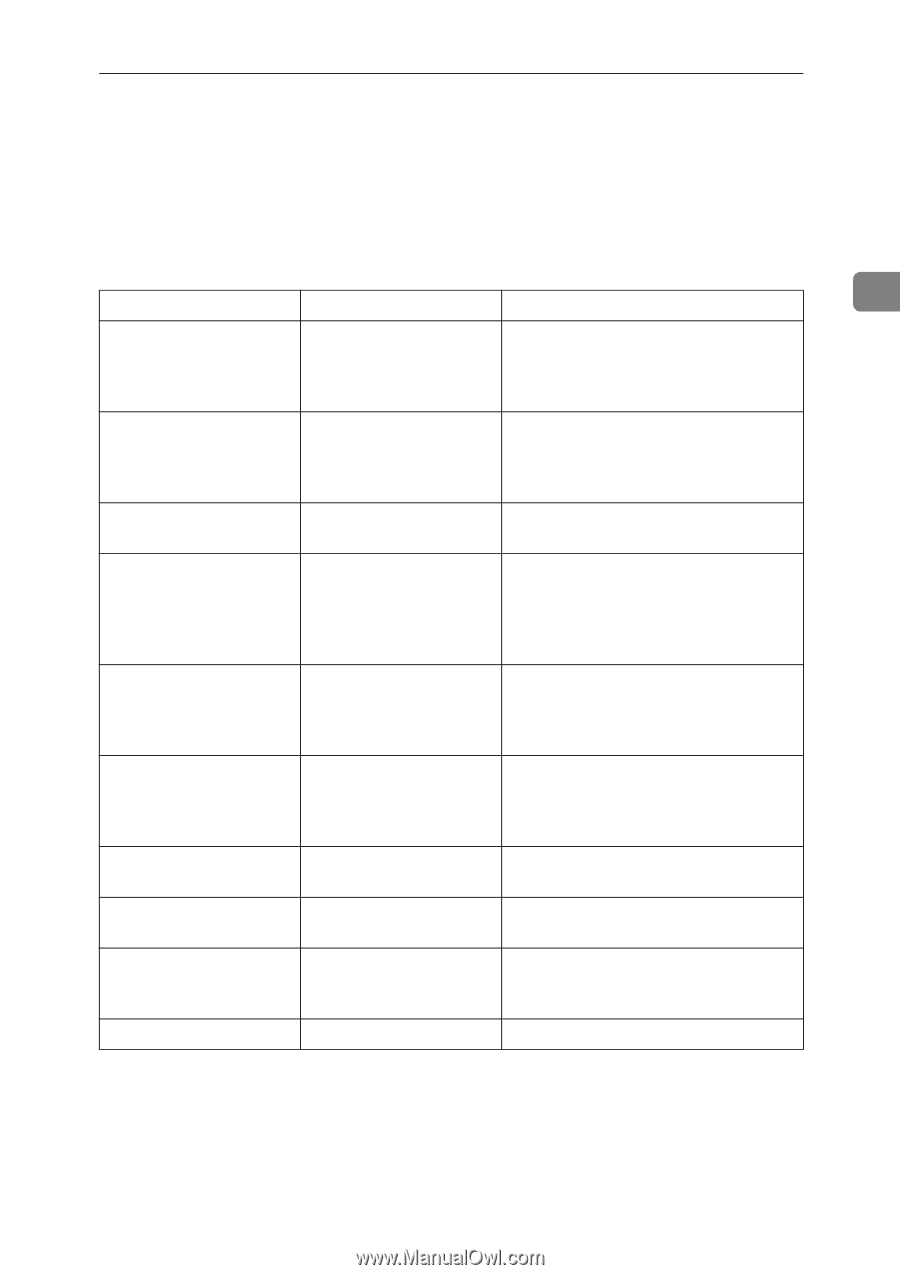

When You Cannot Make Copies As Wanted When You Cannot Make Copies As Wanted This section explains likely causes of and possible solutions for unclear copies. ❖ Basic Problem Cause Solution 2 Misfeeds occur frequently. The number of sheets Load paper only as high as the upper loaded exceeds the capac- limit markings on the side fence of the ity of the machine. paper tray or bypass tray. See "Copy Paper", About This Machine. Misfeeds occur frequent- The paper is damp. ly. Use paper that has been stored in the recommended temperature and humidity condition. See "Copy Paper", About This Machine. Misfeeds occur frequent- The paper is too thick or Use recommended paper. See "Copy ly. too thin. Paper", About This Machine. Misfeeds occur frequent- The copy paper is wrin- ly. kled or has been fold- ed/creased. Use recommended paper. Use paper that has been stored in the recommended temperature and humidity condition. See "Copy Paper", About This Machine. Misfeeds occur frequent- Printed paper is being ly. used. Use recommended paper. Do not use paper that has been already copied or printed onto. See "Copy Paper", About This Machine. Copy paper becomes creased. The paper is damp. Use paper that has been stored in the recommended temperature and humidity condition. See "Copy Paper", About This Machine. Copy paper becomes creased. The paper is too thin. Use recommended paper. See "Copy Paper", About This Machine. Copies are not stapled. There are jammed staples Remove jammed staples. See p.94 "Re- in the stapler. moving Jammed Staples". Copies are not stapled. The number of copies ex- Check the stapler capacity. See "Sup- ceeds the capacity of the plementary Informations", Copy/Doc- stapler. ument Server Reference. Copies are not stapled. Copy paper is curled. Turn the copy paper over in the tray. 29