Brother International RH-9820 Instruction Manual - English - Page 102

Adjusting the positions of the work clamp plates

|

View all Brother International RH-9820 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 102 highlights

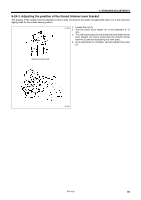

9. STANDARD ADJUSTMENTS 9-20. Adjusting the positions of the work clamp plates Adjust the positions of the work clamp plates (3) so that the throat plate (1) and needle plates (2) do not touch during sewing. The standard adjustment is when there is a gap of 0.8 mm between the throat plate (1) and the needle plates (2) (when the cutting space is set to "0"). * Carry out adjustment for both the left and right work clamps. (The adjustment method described below is for the position of the right-side work clamp plate (3).) * Carry out adjustment with the work clamp plates (3) installed. 0512B 1. Use the parameter settings to set the cutting space to "0". (Refer to "5-3. Program setting method".) * If you press shortcut key 3 (4), you can then change the value simply by pressing the / keys (5) 2. Press the TEST key (6) to turn on test mode, and then start test operation. (Refer to "5-4. Checking the sewing pattern in test mode".) 3. Press and hold the start switch (7) until the feed base moves to the position where the straight section of the sewing shape is sewn, and then release the start switch (7). (when using a 2-pedal foot switch) 0462B Straight section 0513B 0514B Narrow gap Wide gap (Seen from the front) (Seen from directly above) 4. Check that there is a gap of 0.8 mm between the throat plate (1) and needle plate R (2). 5. If there is not a gap of 0.8 mm, loosen the nut (8), and then turn the bolt (9) to adjust. 6. Once adjustment is complete, tighten the nut (8). 7. Press the RESET key (10), and then press the STOP switch (11) to end test mode. * Adjust the gap between the throat plate (1) and needle plate L in the same way. 93 RH-9820