Brother International RH-9820 Instruction Manual - English - Page 85

Adjusting the needle and looper timing, STANDARD ADJUSTMENTS, inside sewing position, loop stroke

|

View all Brother International RH-9820 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 85 highlights

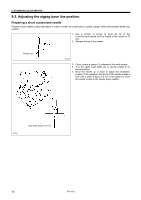

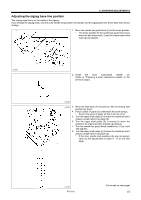

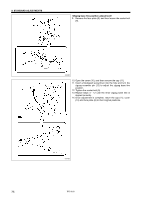

9. STANDARD ADJUSTMENTS 9-4. Adjusting the needle and looper timing NOTE: The needle bar moves through two needle drop cycles for each single turn of the upper shaft pulley. The needle drop movement toward the left side (knife cutting side) is called the "inside sewing position", and the needle drop movement toward the right is called the "outside sewing position". In addition, the amount of movement involved when the needle bar rises from its lowest position until the tip of the looper at either the left or right is aligned with the center of the needle is called the "loop stroke". The left and right loop strokes must be the same as each other. This section describes the adjustments to be carried out so that the left and right loop strokes are the same. * Before carrying out these adjustments, set the zigzag width (stitch width). (Refer to "9-2. Adjusting the zigzag width (stitch width)".) Lowest position of needle bar When center of needle is aligned with tip of looper = for the outside sewing position in the same way as for the inside sewing position. * For the inside sewing position, align the tip of the eye looper (6) with the needle center (7), and for the outside sewing position, align the tip of looper R (8) with the needle center (7). 8. Loosen the screw (9). 9. Move the LS holder base (10) to the left or right to adjust so that length and length