Brother International RH-9820 Instruction Manual - English - Page 82

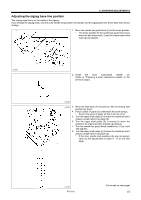

Adjusting the zigzag base line position, Preparing a short customized needle

|

View all Brother International RH-9820 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 82 highlights

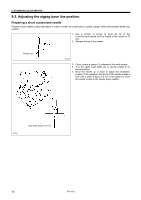

9. STANDARD ADJUSTMENTS 9-3. Adjusting the zigzag base line position Preparing a short customized needle Prepare a short needle as described below in order to make very small holes in a piece of paper while checking the needle drop position. 1. Use a grinder or similar to grind the tip of the currently-used needle until the length of the needle is 15 mm. 2. Sharpen the tip of the needle. Sharpen tip 0563B 3. Place a piece of paper (1) underneath the work clamps. 4. Turn the upper shaft pulley (2) to set the needle to its lowest position. 5. Move the needle up or down to adjust the installation position of the needle so that the tip of the needle makes a hole with a width of about 0.5 mm in the paper (1) when the needle comes to the needle down position. 0564B Hole width approx. 0.5 mm 73 RH-9820