Intermec PM4i PM4i Mid-Range Printer User's Manual - Page 114

SETUP, MEDIA, MEDIA TYPE, To adjust the LSS

|

View all Intermec PM4i manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 114 highlights

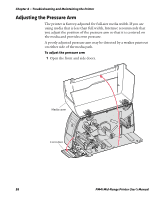

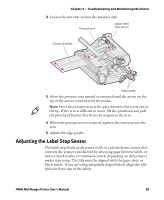

Chapter 4 - Troubleshooting and Maintaining the Printer The LSS can be moved laterally from the inner edge of the media path to 57 mm (2.24 in) outward, which corresponds to the center line of full width media. One part of the sensor is on the upper media guide and the other part of the sensor is under the lower guide. To adjust the LSS 1 Use a slotted screwdriver to turn the adjustment screw. • Rotate the screw clockwise to move the sensor toward the center section. • Rotate the screw counterclockwise to move the sensor outward, away from the center section. Point of detection Adjustment screw 2 Look at the print mechanism from the front with the printhead lifted to make sure that the point of detection on the upper sensor is aligned with the center of the slots or marks in the media. To test the LSS 1 Make sure that your printer is properly configured for the type of media you are using. Go to SETUP > MEDIA > MEDIA TYPE. 2 Open the right door. 3 Lift and lower the printhead. 4 Press the B button. 5 Make sure there is a label (not a gap or mark) at the LSS. 100 PM4i Mid-Range Printer User's Manual