Craftsman #10402 Operation Manual - Page 28

Tightening, The Arm, Column, Adjusting

|

View all Craftsman #10402 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 28 highlights

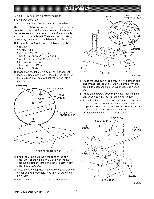

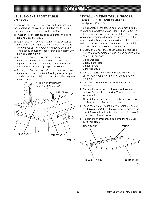

TiGHTENiNG THE ARM AND COLUMN See Figure 19. There should be no play, vertical or horizontal, in the arm relative to the column. If you can move the arm up, down or sideways when the arm lock is unlocked, use the following steps to tighten the arm. Note: The arm should pivot only when the arm lock knob is unlocked and pulled forward to compress the spring. [] Using a phiiJips screwdriver, remove the rear cover screws (2) and rear cover from the back of the arm. This uncovers the bolts on the column. [] Tighten the top two bolts evenly until the arm is firm and there is no vertical or horizontal movement. [] Also check the two bottom hex nuts. It is not necessary to tighten them as tight as the upper bolts. However they should be tightened even and snug. [] Replace the rear cover and rear cover screws. [] Tighten screws securely. REAR COVERSCREWS REAR COVER ADJUSTING THE COLUMN TUBE See fLgures 20A - 20D. The purpose of this procedure is to check whether the inner coJumn tube is snug in the housing and to remove any looseness. Looseness could result in a poor cut or difficulty in elevating the carriage. The coJumn tube is the upper portion of the column and extends from the column support. Note: It is critical to remove alJ looseness with this procedure. If this procedure is not done correctly, folJowing adjustments will be wrong and could result in machine damage. This procedure checks both the elevating action and the rotating action. If a check does not show looseness, do not perform the adjustment. [] if the arm is not at 0 ° (straight forward), release the arm lock knob, set the arm, and reqock the arm lock knob. [] Elevation Check: To check the elevation move- ment, place your hand under the front of the radial arm. Press upward on the radial arm. There should be minimal play between the column tube and the column support. The whole assembly should move as one. See Figure 20A. HEXBOLT (2) COLUMN SUPPORT Fig. 20A HEX NUT(2) Fig. 19 CRRF[_MRN RADIAL SAW 315.220100 28