Craftsman #10402 Operation Manual - Page 62

Squaring, the Blade to the, Fence, Adjustments, Adjusting, Assembly, Setting the Arm Lock

|

View all Craftsman #10402 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 62 highlights

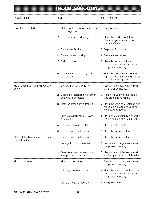

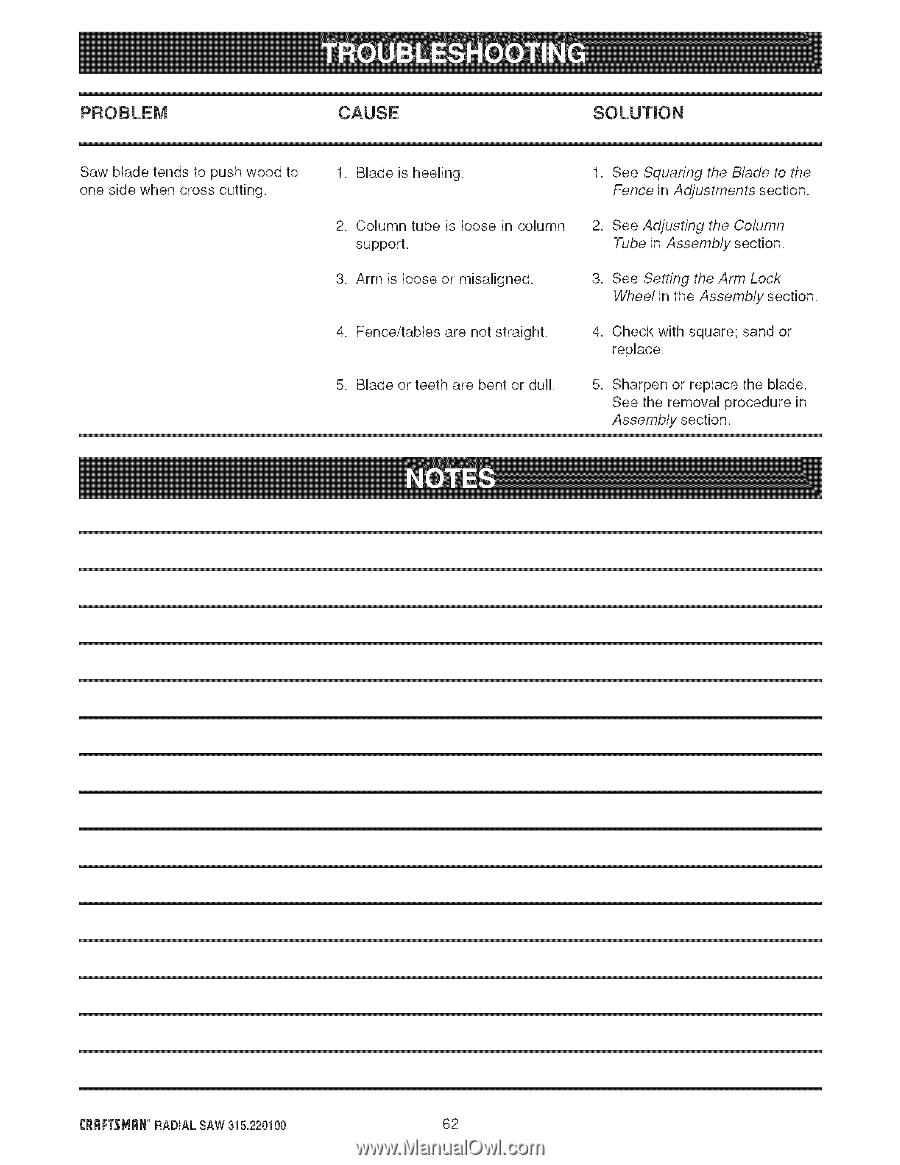

PROBLEM CAUSE SOLUTION Saw Made tends to push wood to one side when cross cutting, 1, BUadeis heeling, 1, See Squaring the Blade to the Fence in Adjustments section, 2, CoUumn tube is Uoose in coUumn support, 2, See Adjusting the Column Tube in Assembly section, 3, Arm is Uoose or misaHgned, 3, See Setting the Arm Lock L,_Zheeinl the Assembly section, 4, Fence/taMes are not straight, 4, Check with square; sand or repUace, 5, BUadeor teeth are bent or dull, 5, Sharpen or repUace the Made, See the removaU procedure in Assembly section, [RRSTSMRN' RADIAL SAW 315.220100 62

PROBLEM

CAUSE

SOLUTION

Saw Made tends to push wood to

1, BUadeis heeling,

1, See

Squaring

the Blade to the

one side when cross cutting,

Fence

in

Adjustments

section,

2,

CoUumn tube is Uoose in coUumn

2,

See

Adjusting

the

Column

support,

Tube

in

Assembly

section,

3, Arm is Uooseor misaHgned,

3,

See

Setting the Arm Lock

L,_Zheel

in the

Assembly

section,

4,

Fence/taMes

are not straight,

4,

Check with square;

sand or

repUace,

5,

BUadeor teeth are bent or dull,

5,

Sharpen or repUace the Made,

See the removaU procedure

in

Assembly

section,

[RRSTSMRN' RADIAL SAW 315.220100

62