Lexmark X7500 Service Manual - Page 22

Operational Pattern 1

|

UPC - 734646391306

View all Lexmark X7500 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 22 highlights

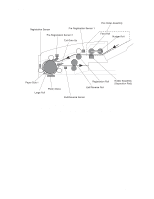

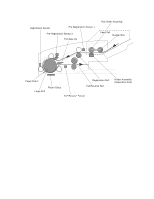

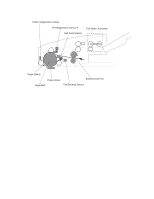

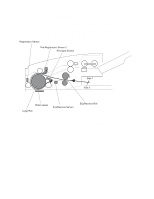

4036-501 Operational Pattern 1 Step 1: Scan of side 1 • The rotation of the nudger roll moves the paper on the DADF tray to the feed roll. • The paper moves to the registration roll by the rotation of the feed roll and the pad in the DADF individual separator pad. • When the pre-registration sensor 1, located just in front of the registration roll, detects the passing of the top of the paper, the paper movement is interrupted for the specified time to synchronize with the paper feed timing. • The paper restarts toward the registration roll. • After passing the DADF upper paper guide, the top of the paper reaches and actuates the paper present sensor flag of the pre-registration sensor 2. • At the position just in front of the large roll, the paper movement is interrupted again for the specified time to synchronize with the paper feed timing. • The paper is moved to the DADF platen glass by rotation of the large roll. • The DADF registration sensor card interrupts the movement for the specified time to synchronize with the scanning timing of the scanner. • The scanner restarts to move the paper to the platen glass by rotation of the large roll. Utilizing the combined mechanism of the large roll rotation and the scanner full rate carriage, side 1 of the paper is scanned. • After scanning, the paper passes the gate through the lower path and moves to the exit/reverse roll. • Along the way, the timing of the exit/reverse sensor detects the pass of the top of the paper. • The paper is stopped by the exit/reverse roll and the reverse roll. • The paper movement is stopped at the time when the end of the paper passes on the exit/reverse sensor. 1-12 Service Manual