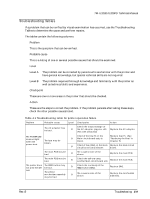

Epson TM U200D Technical Reference - Page 88

Troubleshooting, Rev.B, Table 4-1 Troubleshooting table for printer operation failure Continued

|

View all Epson TM U200D manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 88 highlights

Table 4-1 Troubleshooting table for printer operation failure (Continued) Problem Probable cause Level Checkpoint Action An incorrect interface cable may be used. Check if the interface cable A matches the printer specifications. Use the correct interface cable. Data from the host is printed incorrectly. For the serial interface models, the printer DIP switch settings do not match the host settings. A Check if the printer DIP switch settings match the host settings. Change the printer DIP switch settings or host settings so that they match. The Main circuit board unit may be bad. B Check the printer using another Replace the Main circuit Main circuit board unit. board unit. The mechanism assembly may be bad. B The cause is none of the above. Replace the mechanism assembly. The PAPER OUT LED does not correctly indicate the status of the paper roll. The near-end detector assembly may be bad. (The near-end detector is an option.) B Check the signal of the nearend detector assembly. Replace the near-end detector assembly. The connector is not inserted correctly. Check if the pin of CR motor A cable is inserted in the connector CN6 of the main circuit board unit. Reinsert the connector. The printer is not initialized. (Home position detection error) The Motor, carriage ass'y may be bad. The Motor, carriage may be bad. B Check the continuity of each terminal. Replace the Motor, carriage asse'y. B The cause is none of the above. Replace the Motor, carriage ass'y. Using an oscilloscope, check if The home position detector ass'y may be bad. B the detection signal is output when print head unit passes above the home position Replace the home position detector ass'y. detector ass'y. The operation of the paper supply may be incorrect. A Check if the paper roll meets the printer specifications. Use the correct paper roll. (See "Paper Specifications" in Chapter 1.) The paper path may be incorrect. Check if the paper supply path Remove any pieces of A is blocked by paper particles or paper, paper particles or foreign materials. foreign materials. Semi-automatic loading is not executed. (Paper is not fed.) The connector is not inserted correctly. Motor, Paper feed may be bad. The Roller, paper hold ass'y may be worn. Make sure that the pin of the PF A motor cable is not inserted in the connector CN6 of the main Reinsert the connector. circuit board. B Check if the motor rotates Replace the Motor, paper during semi-automatic loading. feed. B Check if the Roller, paper hold Replace the Roller, paper are worn or damaged. hold ass'y. The gears may be worn or damaged. B Check if the Gear, paper feed reduction and Gear, paper feed are worn or damaged. Replace any worn or damaged parts. The Paper detection switch ass'y may be bad. B Using an oscilloscope, check if the detection signal is output when roll paper is inserted. Replace the Paper detection switch ass'y. 4-10 Troubleshooting Rev.B