Honeywell Heat/1Cool User Guide - Page 24

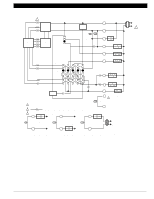

Fig. 27. Typical wiring diagram for T8611M7008.

|

View all Honeywell Heat/1Cool manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 24 highlights

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE THERMOSTAT LOGIC CIRCUIT POWER SUPPLY SUBBASE LOGIC/ CONTROL CIRCUIT FAN SWITCH ON AUTO S1 S1 S2 S2 S3 S3 6 200905 REMOTE SENSOR HEAT 1 HIGH LIMIT 5 HIGH LIMIT EM. HT. LED (RED) R 4 3 C AUX. HT. LED (GREEN) L MONITOR AUX. HT. RELAY W3 HEAT 3 STAGE 2 RELAY W2 HEAT 2 EM. HT. RELAY E SYSTEM SWITCH EM. HT. HEAT OFF AUTO COOL COOL 1 FAN RELAY G COOL CHANGEOVER C. O. VALVE O C. O. HEAT CHANGEOVER VALVE B STAGE 1 COMPRESSOR CONTACTOR Y STAGE 2 COMPRESSOR CONTACTOR Y2 COOL 2 X1 2 CHECK LED (YELLOW) X2 L1 (HOT) L2 1 1 POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED. 2 POSSIBLE CHECK LED CIRCUITS: X1 TO R CHECK LED FAULT DETECTION SWITCH (YELLOW) X2 TO C X1 TO R CHECK LED (YELLOW) FAULT DETECTION SWITCH X2 TO C X1 CHECK LED SWITCHING DEVICE (YELLOW) 24 VAC X2 L1 (HOT) L2 SWITCH TO R (POWER) SIDE OF SYSTEM TRANSFORMER SWITCH TO C (COMMON) SIDE OF SYSTEM TRANSFORMER SWITCH IN SECONDARY OF SEPARATE TRANSFORMER 3 SOME OLDER HEAT PUMP THERMOSTATS USE X FOR COMMON TERMINAL. 4 NOMINAL 24 VAC POWER MUST BE PRESENT BETWEEN R AND C TERMINALS FOR THERMOSTAT OPERATIONS. 5 AVAILABLE ONLY ON MODLES WITH SEPARATE SENSOR FOR REMOTE TEMPERATURE SENSING. 6 RECOMMENDED INTERCONNECT CABLE: 18-GAUGE THERMOSTAT CABLE, 200 FT. (61 M) MAXIMUM LENGTH. ROUTE INTERCONNECT CABLE AWAY FROM SOURCES OF ELECTRICAL NOISE. Fig. 27. Typical wiring diagram for T8611M7008. M2656 70-6627 • 22