Troy-Bilt Horse Tiller Technical Manual - Page 28

Tiller, Attachment, Transmission

|

View all Troy-Bilt Horse Tiller manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 28 highlights

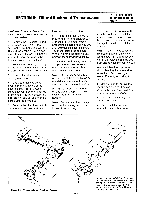

PTO HORSE MODEL TECHNICAL MANUAL Page 6-1 4/90 SECTION 6: Tiller Attachment Transmission This section describes the the procedures for servicing the tiller attachment transmission. A WARNING: When servicing the machine, prevent unintentional starting of the engine by disconnecting the spark plug wire and keeping the wire away from the spark plug. Place the engine throttle control in the OFF position and shift the Wheels/Tines/PTO Drive Lever into NEUTRAL. Tiller Drive Shaft Assembly These instructions describe how to remove, inspect, and install the tiller attachment's drive shaft. Use Figure 6-1 as a reference for part locations in these instructions. Note: Either of two basic types of drive shafts may have been installed at the factory: an integral worm design (the worm is machined directly from the shaft material), or a welded worm design (the worm is welded to the shaft and can be identified by blue welds at either end of the worm). Each design has its own part number and requires specific related parts. Before installing a new drive shaft or related drive shaft parts, first determine which type of shaft you are working with. See the tiller parts catalog for parts ordering information. Removal 1. Set the tiller housing in a vise and tighten the vise jaws around the metal plate that contains the bolt hole for the depth regulator drag bar (see Figure 6-1). 2. Push the dog clutch (1) into the housing (the clutch is under spring tension) until you see the forward (external) snap ring (2) that retains the dog clutch. Then remove the snap ring with a pair of snap ring pliers. 11 16 12 10 13 V " 14 Iv y TILLER HOUSING HOLE FOR DEPTH REGULATOR TILLER TINE SHAFT Figure 6-1: Tiller Attachment Drive Shaft Assembly. 103