Troy-Bilt Horse Tiller Technical Manual - Page 9

Leaks

|

View all Troy-Bilt Horse Tiller manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 9 highlights

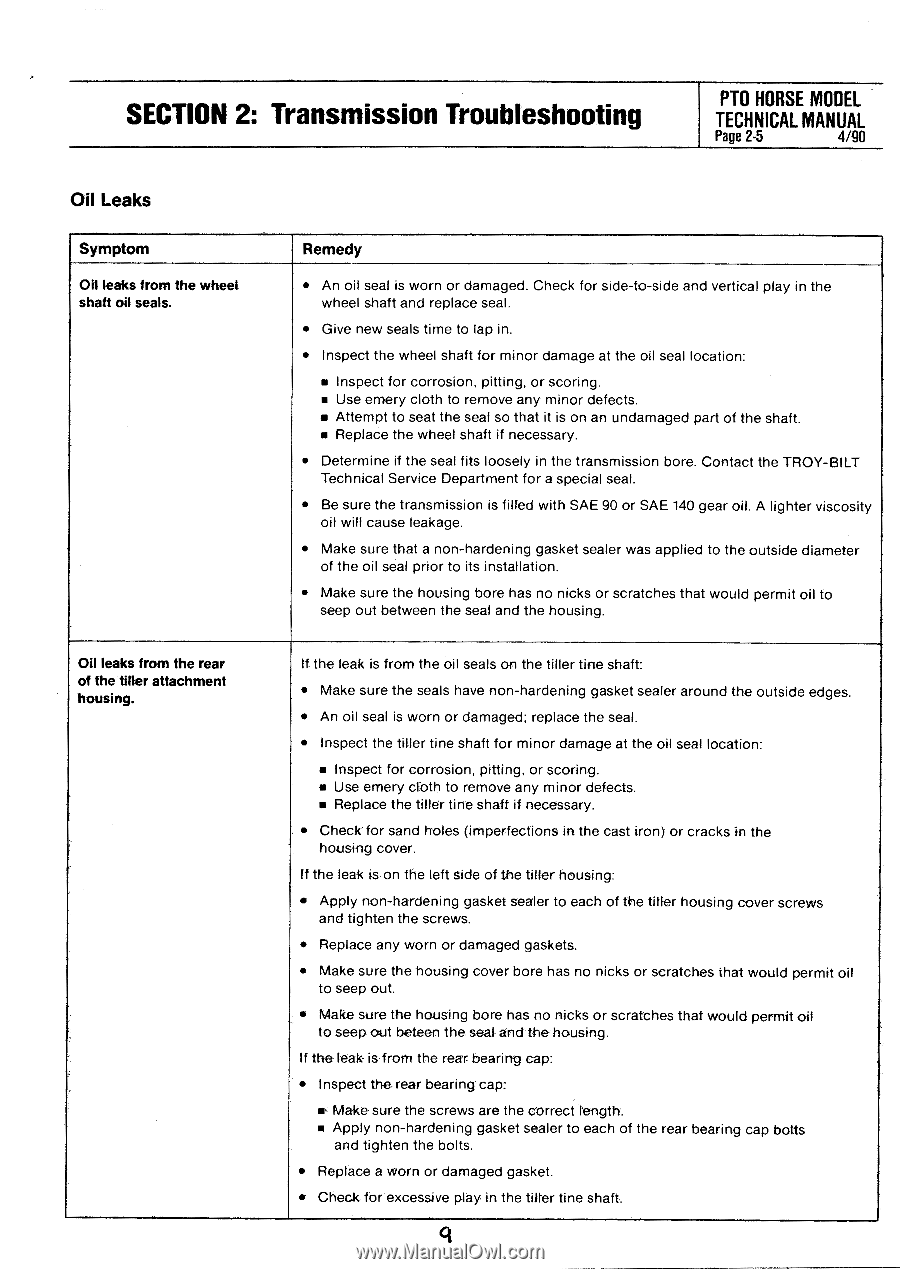

SECTION 2: Transmission Troubleshooting PTO HORSE MODEL TECHNICAL MANUAL Page 2-5 4/90 Oil Leaks Symptom Oil leaks from the wheel shaft oil seals. Oil leaks from the rear of the tiller attachment housing. Remedy • An oil seal is worn or damaged. Check for side-to-side and vertical play in the wheel shaft and replace seal. • Give new seals time to lap in. • Inspect the wheel shaft for minor damage at the oil seal location: ■ Inspect for corrosion, pitting, or scoring. ■ Use emery cloth to remove any minor defects. ■ Attempt to seat the seal so that it is on an undamaged part of the shaft. ■ Replace the wheel shaft if necessary. • Determine if the seal fits loosely in the transmission bore. Contact the TROY-BILT Technical Service Department for a special seal. • Be sure the transmission is filled with SAE 90 or SAE 140 gear oil. A lighter viscosity oil will cause leakage. • Make sure that a non-hardening gasket sealer was applied to the outside diameter of the oil seal prior to its installation. • Make sure the housing bore has no nicks or scratches that would permit oil to seep out between the seal and the housing. If the leak is from the oil seals on the tiller tine shaft: • Make sure the seals have non-hardening gasket sealer around the outside edges. • An oil seal is worn or damaged: replace the seal. • Inspect the tiller tine shaft for minor damage at the oil seal location: ■ Inspect for corrosion, pitting, or scoring. ■ Use emery cloth to remove any minor defects. ■ Replace the tiller tine shaft if necessary. • Check for sand holes (imperfections in the cast iron) or cracks in the housing cover. If the leak is on the left side of the tiller housing: • Apply non-hardening gasket sealer to each of the titter housing cover screws and tighten the screws. • Replace any worn or damaged gaskets. • Make sure the housing cover bore has no nicks or scratches that would permit oil to seep out. • Make sure the housing bore has no nicks or scratches that wou►d permit oil to seep out beteen the seal and the housing. If the leak is from the rear bearing cap: • Inspect the rear bearing cap: ■ Make sure the screws are the correct length. ■ Apply non-hardening gasket sealer to each of the rear bearing cap bolts and tighten the bolts. • Replace a worn or damaged gasket. • Check for excessive play in the tiller tine shaft.