HP Color 9850mfp Service Manual - Page 470

Punching process, Movement of the standby position of the punch unit, Movement of the standby position

|

View all HP Color 9850mfp manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 470 highlights

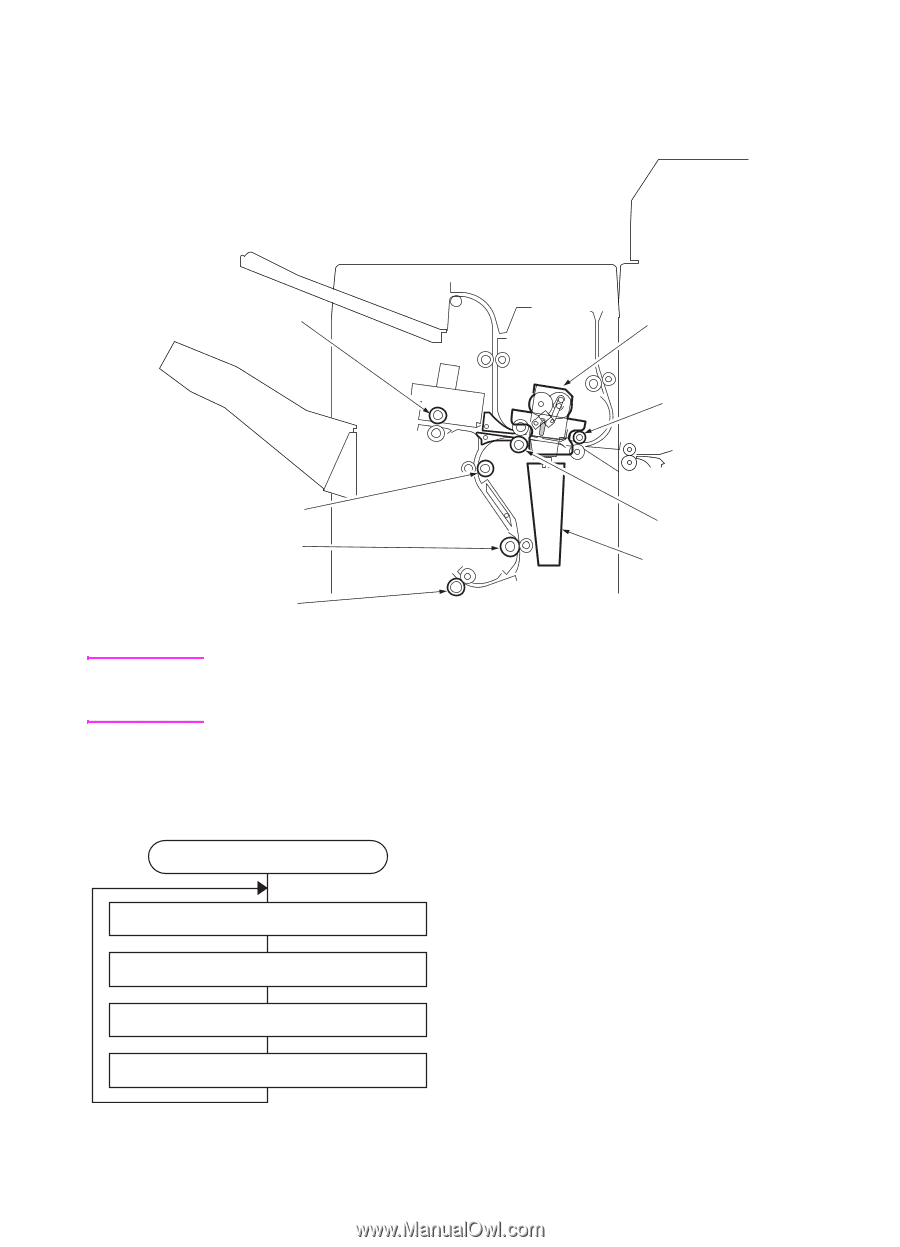

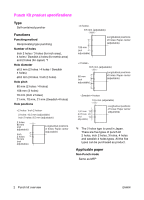

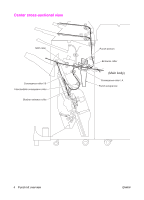

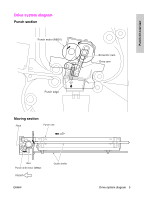

Punching process Punch Kit consists of the following sections: Shift roller Punch section Entrance roller Conveyance roller / B Intermediate conveyance roller Stacker entrance roller (Main body) Conveyance roller / A Punch scraps box Note The punching process differs between the punch mode (holes are made) and non-punch mode (no holes are made). Either of these modes can be selected on the control panel of the MFP. The following flowchart shows the flow of operations performed by the above sections. These operations are explained according to this flowchart. Start Movement of the standby position of the punch unit Formation of a Registration Loop Correction of the punch position Punch Movement of the standby position of the punch unit When the punch mode is selected, the punch shift motor (M802) runs to move the punch unit so that the paper edge sensor mounted on the punch unit is placed inside of the side edge of paper by 5 mm. However, if the paper size is Letter, Legal, or 5.5 by 8.5R, the sensor is positioned by 10 mm inside. The above operation is not generally performed in the non-punch mode, however, for the paper sizes shown below, the punch unit is moved to the position located inside of the side edge of paper by 10 mm in order to secure the easy feeding of paper when conveyed. 6 Punch kit overview ENWW