HP Color 9850mfp Service Manual - Page 478

A5 / A5R / B5R / A4 / A4R / B4 / A3, passage/U or PS206 PI passage/L

|

View all HP Color 9850mfp manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 478 highlights

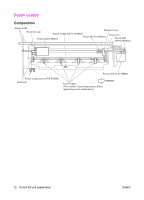

c Detecting the side edge reference position When the finisher entrance PS (PS704) detects the leading edge of paper, M802 (punch shift) runs again to move the punch unit backward temporarily until the paper edge sensor detects the side edge of the paper. If punching is performed for the paper conveyed from PI, the time when PS201 (PI passage/U) or PS206 (PI passage/L) detects the leading edge of the paper is the starting point. Subsequently, M802 runs inversely to move the punch unit frontward until the paper edge sensor re-detects the side edge of the paper. This position becomes the side edge reference position. d Moving the punch position When the side edge reference position is detected, M802 (punch shift) moves the punch unit again so that the center of punch edges is positioned to the center of paper. The distance and direction of this movement differ from paper sizes. Only when moving backward, the punch unit makes a stop at the side edge reference position. The direction of the movement from the side edge reference position to the punch position classified by paper sizes is as follows: Frontward: A5 / A5R / B5R / A4 / A4R / B4 / A3 / Letter / 8.5 by 14 / 5.5 by 8.5 / 5.5 by 8.5R / 8K / 16K / 16KR Backward: B5 / F4 / Letter R / Ledger The series of movement from c. Detecting the side edge reference position to d. Moving the punch position is performed per each paper, and these movements correct the punch position. e Forming a registration loop M701 (finisher conveyance) turns off temporarily a specified time after PS37 (paper exit) detects the leading edge of the paper to form a loop at the entrance roller. If punching is performed for the paper conveyed from PI, the loop will be formed on the PI's side. f Punch movement When finisher entrance PS (PS704) detects the trailing edge of the paper, M801 (punch) runs and performs the punch movement. For some paper sizes, the punch movement is executed before completing the correction of the punch position for the punch unit. To avoid this, switch the conveyance speed on finisher to a low speed only for such paper size. Paper size A5 / 5.5 by 8.5R Other sizes Conveyance speed 345 mm/s 670 mm/s If punching is performed for the paper conveyed from PI, the time when the trailing edge of the paper is detected by PS206 (PI passage/L) is the starting point. g Paper edge sensor To detect the side edge of the paper, the paper edge sensor mounted on the punch unit is used. The paper edge sensor consists of 5 sensors shown in the below figure. Which sensor is used depends on the paper sizes. Paper edge sensor Direction of paper conveyance 14 Punch kit unit explanation ENWW