HP Indigo WS6000 Indigo High Quality Color Control HQCC Process for PSPs and B - Page 17

Baseline and maintenance (PSP), Preferred Spectrophotometer Model

|

View all HP Indigo WS6000 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 17 highlights

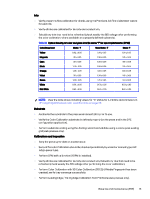

Refer to Refine Spot Colors: Delta-E Tolerance (General Preferences) on page 42. ○ In the Preferred Ink Book section: ● Create a new Ink Book for the Brand. NOTE: Ink books are used to define custom spot colors. A different ink book may be selected if preferred. As a starting point, it is recommended to use the default 'designer' ink book until you are more familiar with their uses. Refer to Map spot colors - Create an Ink Book on page 43. ○ In the Color Strategies section: ● Set the Input Profile to Same as Output Profile. ● Set the Output Profile to Last Used Profile. - Click the Spectrophotometer button, and set the following: ○ Preferred Spectrophotometer Model - It should match the installed hardware. ○ Preferred Measurement Condition - M0 NOTE: Measurement condition - For inline measurements using the closed-loop feature, the SPM currently on-board measures only in M0 condition. ○ For "When starting a wizard that supports inline measurement" select the option Ask me every time I start the wizard. ○ Click OK to close the Preferences window. ● Proceed to the Baseline and Maintenance procedures (including the Color-related baseline procedure) - See Baseline and maintenance (PSP) on page 13. Baseline and maintenance (PSP) Ensure the press is well maintained and calibrated. ● Allocate a dedicated time frame for maintenance, including monitoring report. See RACI table (Roles / Responsibilities Assignment Matrix) on page 38. ● Verify all maintenance routines are performed - Refer to Production Excellence Routines Maintenance Checklist (CA394-14431). ● Perform the FSE routines on each FSE visit, as per the checklist below: FSE routines checklist - Check 2nd transfer calibration. - Verify the software last update using HP Indigo Radar. - Check all ink density and conductivity. - Close all open service calls. - Verify the writing head PQ outputs. Baseline and maintenance (PSP) 13