HP Indigo WS6000 Indigo High Quality Color Control HQCC Process for PSPs and B - Page 19

Ink Flow Calibration, Scaling

|

View all HP Indigo WS6000 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 19 highlights

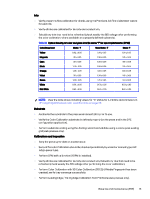

Inks ○ Verify proper ink flow calibration for all inks using the PrintCare Ink Flow Calibration wizard for each ink. ○ Verify all inks are calibrated for density and conductivity. ○ Rebuild any inks that need to be refreshed (check weekly the BID voltage after performing the color calibration, where available, on a properly defined substrate). Table 3-1 Optical density per color and gloss level (in status "T" for spectrophotometer (SPM)) Color/Gloss level Matte - T Semi-Matte - T Gloss - T Yellow 0.82 ± 0.05 0.91 ± 0.05 1.00 ± 0.05 Magenta 1.10 ± 0.05 1.30 ± 0.05 1.45 ± 0.05 Cyan Black 1.10 ± 0.05 1.20 ± 0.05 1.30 ± 0.05 1.50 ± 0.05 1.45 ± 0.05 1.75 ± 0.05 Orange 1.35 ± 0.05 1.65 ± 0.05 1.90 ± 0.05 Violet 1.10 ± 0.05 1.30 ± 0.05 1.45 ± 0.05 Green White 1.05 ± 0.05 0.53 ± 0.05 1.25 ± 0.05 0.53 ± 0.05 1.40 ± 0.05 0.53 ± 0.05 Std. White 0.82 ± 0.05 0.82 ± 0.05 0.82 ± 0.05 NOTE: View the table above including values for "G" status for ILD (inline densitometer), in HP Indigo Digital Presses color specifications on page 40. Substrate ○ Acclimate the substrate to the press environment 24 hr prior to use. ○ Verify the Color Calibration substrate is defined properly (on the press and in the DFE configuration application). ○ Perform substrate scaling using the Scaling wizard and validate using custom quick scaling grid (web presses only). Calibrations and Inspection ○ Keep the press up-to-date on maintenance. ○ Second Transfer Calibration should be checked periodically by wizard or manually (per HP Indigo press type). ○ Perform SPM self calibration (if SPM is installed). ○ Verify all inks are calibrated for density and conductivity. Rebuild any inks that need to be refreshed (check weekly the BID voltage after performing the color calibration). ○ Perform Color Calibration with 3D Color Calibration (3DCC) (if Media Fingerprint has been created); verify they converge successfully. ○ Perform Leading Edge / Trailing Edge Calibration from PrintCare (web presses only). Baseline and maintenance (PSP) 15