HP Indigo WS6000 Indigo High Quality Color Control HQCC Process for PSPs and B - Page 20

Color Management on HP Indigo Digital, Presses How-to Guide

|

View all HP Indigo WS6000 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 20 highlights

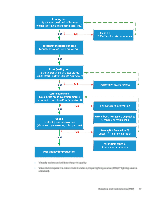

Validation / Press daily linearization NOTE: Refer to Baseline and maintenance (PSP) on page 13. ○ Validate Optical Density (OD) via QC target job. ○ Print 10-20 QC job frames and measure 100% solid and 75%, 50%, 25%, 5% dot area (DA) color patches for each process color on one or two sheets from the middle of the run. ○ Verify average Optical Density (OD) is within specification tolerances (± 0.05 OD and ± 5% DA for each process color), as described in the "Color Management on HP Indigo Digital Presses How-to Guide". ○ Review PQ troubleshooting steps if QC target job results indicate print quality issues. Refer to the "Press daily linearization procedure flow" below. (The purpose of this procedure is to ensure that the press reaches the standard and reproduces optimal outputs). Press Daily Linearization procedure flow 16 Chapter 3 Detailed production processes