HP Indigo WS6000 Indigo High Quality Color Control HQCC Process for PSPs and B - Page 40

A. Appendix, Pre-visit agenda and questionnaire, Use

|

View all HP Indigo WS6000 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 40 highlights

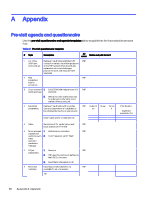

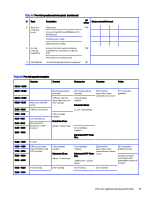

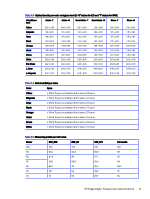

A Appendix Pre-visit agenda and questionnaire Use the pre-visit questionnaire and agenda templates below as guidelines for the production process flow. Table A-1 Pre-visit questionnaire template # Topic Description A/I owner Status and path forward 1 List of the Retrieve from the brand all the L*a*b* PSP L*a*b* spot spot colors values that will be produced colors values at the PSP session (allow to evaluate optimal ink set, color challenges, prepare ink book and measurement template) 2 Real PSP production jobs for simulation 3 Color standard 1. 2.0 ΔE 2000 with weight factor 1.1.1 PSP and tolerances standard. 2. Where the color standard stands for (after print, after lamination/ varnish or final product?). 4 Substrate parameters Retrieve from the Brand the number, type and parameters of substrates to be validated during the on-site session PSP Substrat Ink set Varnis es h Prioritization (Expected production %) Order substrate for on-site session 5 Press Send press # for performance and PSP issue evaluation in PrintOS 6 To be reviewed, 1. Maintenance procedure. PSP aligned and confirmed with 2. Color frequency set to "High". press operator/ production manager 7 QC job preparation 1. Base job PSP 2. PSP specific patches as defined in the HQCC procedure. 3. Send the final template to HP. 8 Tools and Exact spectrophotometer to be PSP materials available for on-site session I1i0 36 Appendix A Appendix