HP Indigo WS6000 Indigo High Quality Color Control HQCC Process for PSPs and B - Page 38

Verify Job Image Placement., Verify Job Repeat Length.

|

View all HP Indigo WS6000 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 38 highlights

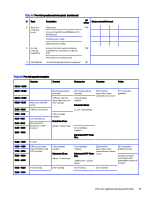

Once all color procedures have been completed, and production can take place, it is important that all Job Properties settings are verified before a job is printed. Communication of chosen standard settings is key to successfully printing jobs. Verify all Job Properties are set according to company standards for every file: ● Copy Count (Quantity) ● Line Screen (example: HDI-175) ● LUT for all colors is set as linear ● Ink Order is correct ● CCC is activated Upon first print or proof: ● Perform full color calibration on relevant substrate. ● Inspect quality of print (PQ) using the QC job - See PQ and color validation (PSP) on page 20. ● Inspect color results by performing full color calibration as defined for High color calibration frequency. Compare results to previously approved print if one exists. If finishing is required, compare unfinished print to unfinished proof for best comparison. ● Verify Job Repeat Length. ● Verify Job Image Placement. ● Create your color reference for future reprint jobs: 1 sample with varnish, and 1 sample after varnish. (Keep all varnish machine parameters: Corona Power, LBS, Anylox, speed, coat weight). If some settings are not as expected, verify: ● Job has been ripped with the correct Strategy. NOTE: ● Communication between management, pre-press and press operator is essential for the success of this procedure. ● It is equally important to ensure that all Job Properties are verified before print. 34 Chapter 3 Detailed production processes