Intel Q9400S Design Guidelines - Page 44

Intel, D60188-001 Reference Design, Exploded View

|

UPC - 735858207973

View all Intel Q9400S manuals

Add to My Manuals

Save this manual to your list of manuals |

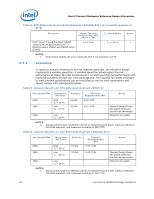

Page 44 highlights

Intel® Thermal/Mechanical Reference Design Information The Intel® Core™2 Quad processor Q6000 series at 105 W requires a thermal solution equivalent to the RCBFH-3 reference design, see Intel® Pentium® 4 Processor on 90 nm Process in the 775-Land LGA Package Thermal and Mechanical Design Guidelines for a complete description of this reference design. The Intel® Core™2 Quad processor Q6000 series at 95 W and Intel® Core™2 Quad processor Q9000 and Q8000 series at 95 W require a thermal solution equivalent to the D60188-001 reference design (see Figure 11 for an exploded view of this reference design). Note: The part number D60188-001 provided in this document is for reference only. The revision number -001 may be subject to change without notice. Figure 11. Intel® D60188-001 Reference Design ─ Exploded View Note: Development vendor information for the Intel® D60188-001 Reference Solution is provided in 0. The D60188-001 reference design takes advantage of an acoustic improvement to reduce the fan speed to show the acoustic advantage (its acoustic results are shown in the Table 6). Note: If the heatsink design is used in the Intel® Core™2 Quad processor Q6000 series at 95 W and Intel® Core™2 Quad processor Q9000 and Q8000 series at 95 W for cost savings instead of acoustic advantage, the design that optimizes cost would likely use aluminum core type designs with the similar fan or a combination of all these (the smaller copper core, the cheater fan and the lower fin density extrusion). 44 Thermal and Mechanical Design Guidelines