Xerox 6180N DocuSP 61xx version 3.6 - Operator Guide - Page 91

WARNING, Remember that the fuser and binder area surfaces are hot., Proceed with caution when

|

UPC - 095205425307

View all Xerox 6180N manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 91 highlights

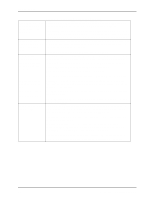

Problem solving WARNING Remember that the fuser and binder area surfaces are hot. Proceed with caution when clearing all jams. Resolving a processor problem Problem Paper tray elevator fails to rise or lower Paper path jams Table 6-1. Resolving a processor problem Suggested solutions Ensure that the stock is loaded properly in the paper trays, with the rear and side guides against the stock stack. If the elevator fails to rise or lower in paper tray 1 or 2, latch the paper feeder by pressing down on the green dot inside the tray. Do not slam the trays closed. Push the trays in slowly but firmly. Ensure that all misfed stock has been removed from the immediate area of the paper trays. Check the area where the jams are occurring to ensure that the paper path is clear of paper and other obstructions. If a jammed sheet of paper tears when being removed, ensure that you have removed all of the sheet pieces. Ensure that the paper path baffles are in the correct seated position. Ensure that the stock is loaded properly in the trays, with the rear and side guides against the stack. Ensure that the stock is not loaded above the bottom of the red line in the paper tray. Ensure that the stock has no bent corners, or tears, and that the edges are straight. Remove any damaged sheets. Repeated jamming may be due to a paper curl problem that can be resolved by adjusting the decurler lever. Refer to the procedure, "Adjusting for paper curl," in this guide. Paper weight less than substance 20 (75 g/m2) will require careful setting of the decurler. Refer to the procedure, "Adjusting for paper curl," in this guide. Fan the stock thoroughly. Ensure that the stock is within the limitations described in the satisfaction guides in the "Technical information" chapter. Paper weight less than substance 20 (75 g/m2) will require careful storage and handling. Refer to the "Technical information" chapter. DocuTech 61xx Operator Guide 6-3