Xerox 6180N DocuSP 61xx version 3.6 - Operator Guide - Page 95

Resolving an interposer problem, Resolving a finisher problem, Table 6-2. Resolving an interposer

|

UPC - 095205425307

View all Xerox 6180N manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 95 highlights

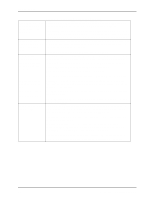

Problem solving Resolving an interposer problem Problem Repeated jams in interposer Table 6-2. Resolving an interposer problem Suggested solutions Follow the jam clearance diagram in the Printer Fault Clearance window carefully to ensure all paper has been cleared. Make sure the stock in trays 4 and 5 have been loaded correctly. Refer to the Satisfaction guides in chapter 4, "Technical Information", for information on loading stock in trays 4 and 5. Make sure the stock in trays 4 and 5 meet the specifications for these trays as indicated in the Satisfaction guides in chapter 4, "Technical Information". Resolving a finisher problem Table 6-3. Resolving a finisher problem Problem Suggested solutions Repeated jams in area The bindexer contains three bins used by the system to sort sets. The 14 (bindexer) capacity of each bin is 125 sheets of substance 20 (75 g/m2) or 0.5 inch (13 mm) thickness. Include inserts and covers when considering the output capacity of the bindexer. 125 sheets of substance 20 (75 g/m2) is equal to approximately: 104 sheets of substance 24 (90 g/m2) 78 sheets of substance 32 (120 g/m2) 47 sheets of substance 110 (200 g/m2). Check that the sets in the bindexer are less than 0.5 inch (13 mm) thick. If the set exceeds 0.5 inch (13 mm) thickness, reprogram the job for fewer sheets or reduce the number of heavy-weight sheets. When running collated, unfinished sets, the maximum sheet capacity of the bindexer can be set between 50 and 125. When running anything other than collated, unfinished sets, the maximum sheet capacity of the bindexer will remain at 125. Jammed binder tape, such as binder tape sticking together, or cosmetic defects in the bound book Replace the tape reel with a new reel using the procedure, "Replacing the binder tape reel," in this guide. Refer to the binder tape reel storage information in this guide. Binder tape not positioned correctly on the top edge of the output prints Adjust the binder tape registration using the procedure, "Adjusting the binder tape registration," in this guide. DocuTech 61xx Operator Guide 6-7