Brother International S-7200B Service Manual - Page 39

Adjusting the thread trimming timing, ADJUSTMENTS, Thread trimming cam position adjustment >

|

View all Brother International S-7200B manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 39 highlights

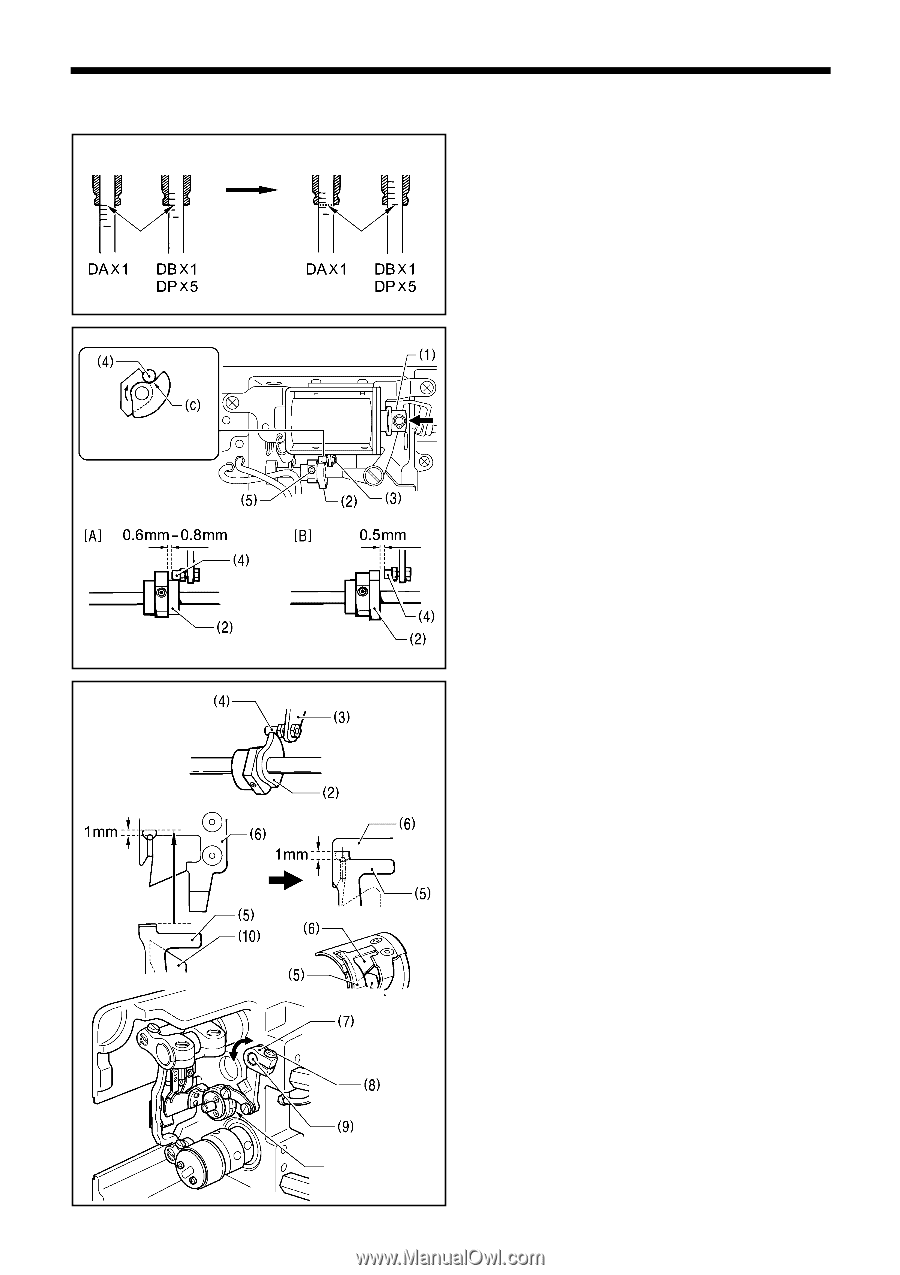

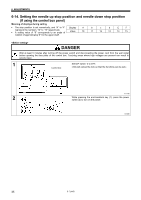

6. ADJUSTMENTS 6-11. Adjusting the thread trimming timing Lowest position of needle bar Raised 5 mm Reference line (a) Reference line (b) Remove the presser foot, needle plate and feed dog. < Thread trimming cam position adjustment > 1. Turn the machine pulley to raise the needle bar 5 mm from its lowest position (reference line (a) position) so that reference line (b) is aligned with the bottom edge of the needle bar bush. Direction of cam rotation 1204B 2. At the above position, push the plunger (1) of the thread trimming solenoid with your finger in the direction of the arrow. Adjust the position of the thread trimmer cam (2) at this time so that the roller shaft (4) of the thread trimmer cam lever assembly (3) touches the hollow (c) of the thread trimmer cam (2) and so that the clearance between the edge of the thread trimmer cam (2) and the roller shaft (4) is 0.6 to 0.8 mm, and then tighten the set screws (5). (Fig. [A]) 3. Check that the clearance between the edge of the thread trimmer cam (2) and the roller shaft (4) is 0.5 mm when the roller shaft (4) returns to the right. (Fig. [B]) * Tighten the two set screws (5) to approximately 4 N.m. 1205B 1206B 1207B 1. Turn the machine pulley, and then push the plunger (1) of the thread trimming solenoid with your finger. 2. In this condition, turn the machine pulley until the roller shaft (4) of the thread trimmer cam lever assembly (3) is sitting on top of the thread trimmer cam (2), then move the thread trimmer lever (7) to adjust its position so that the tip of the fixed knife (5) and the blade of the movable knife (6) are meshed by 1 mm, and then tighten the screw (8). * Adjust so that the meshing amount is 1 mm at this time, by using the position where the mating marks on the thread trimmer holder and the bushing are aligned as a guide. * Tighten the screw (8) so that there is no play in the forked shaft (9). * The lower thread finger (10) must be underneath the movable knife (6). 3. Install the feed dog, needle plate and presser foot. Mating mark 1208B S-7200B 32