HP 450c HP DesignJet 430, 450C, and 455CA Printer - User's Guide - Page 109

Test 5, Color Variation, Test 6, Banding Test - ink cartridge

|

View all HP 450c manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 109 highlights

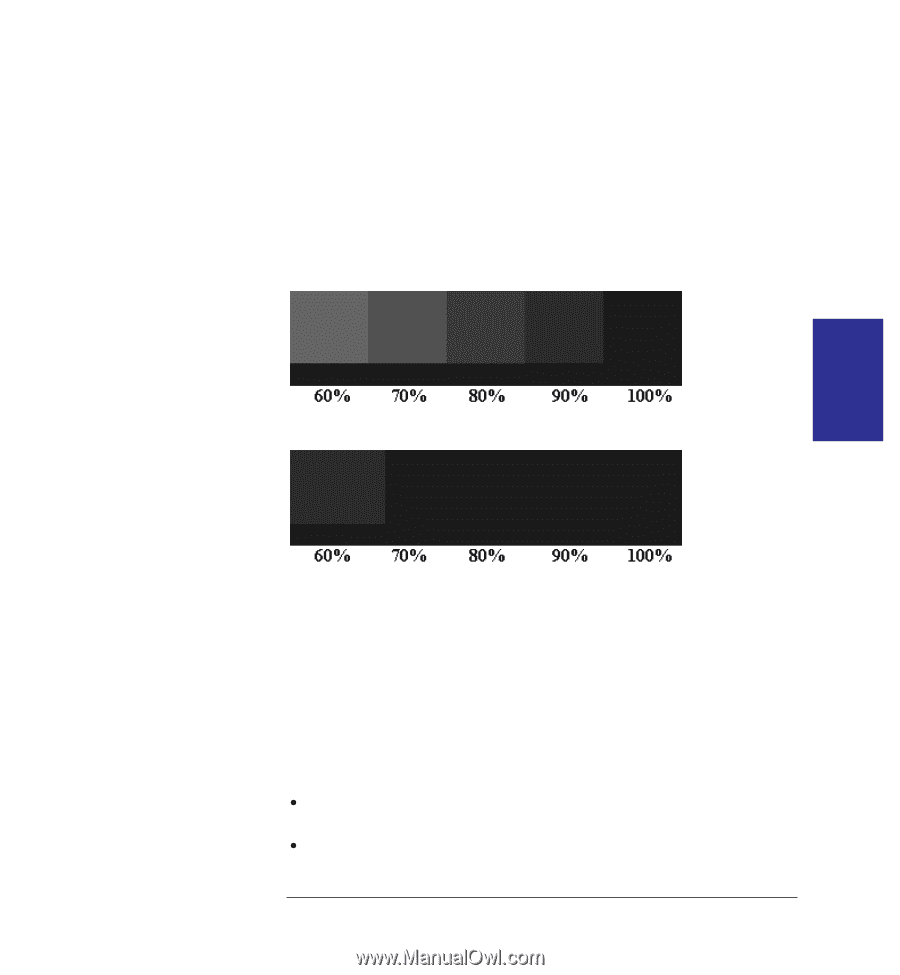

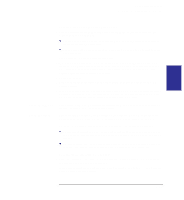

INTERNAL 5 PRINTS Special internal prints Using the Print Quality Test Print Test 5 (Color Variation) This test produces four boxes in yellow, black, cyan and magenta. In each box there are two horizontal bands; the lower band is a 100% shade, the upper band is shaded from 100% scaling to 60%. The purpose of this test is to determine at what percentage the upper shading becomes visible from the lower band. The best way to do this is to cover the box with a piece of paper and slide the paper horizontally across the box. Stop as soon as you see a different shade in the upper box. You can then determine the percentage scaling from the figure at the top or bottom of the box. Correct Incorrect If the upper box shading is never visible or is visible only at a very low percentage, it is an indication that the cartridge is producing incorrect size ink drops. Try the following: 1 Replace the failing cartridge and print the Print Quality Test Print again. Test 6 (Banding Test) This test pattern is a long dark stripe and is not numbered on the Print Quality Test Print. It can be found on the left-hand side of the other test patterns. Banding consists of random dark or light bands in area fills. There are two types of banding: Negative banding: This means that consecutive swaths overlap each other, creating dark bands. Positive banding: This means that consecutive swaths do not touch, thus leaving a small gap between each other. This then causes white (or lighter colored) bands. 5-17