HP Color LaserJet Enterprise CP4525 HP Color LaserJet Enterprise CP4020/CP4520 - Page 55

Print Test Manual Sensor Test

|

View all HP Color LaserJet Enterprise CP4525 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 55 highlights

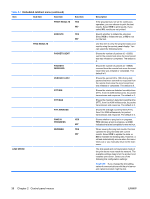

Item Sub-item PAPER PATH SENSORS PAPER PATH TEST PRINT TEST PAGE SOURCE DUPLEX COPIES MANUAL SENSOR TEST MANUAL SENSOR TEST 2 COMPONENT TEST A list of available components appears. PRINT/STOP TEST Values Description Performs a test on each of the product's sensors to determine if they are working correctly and displays the status of each sensor. Tests the paper-handling features of the product, such as the configuration of the trays. Generates a page for testing the paper-handling features. You must define the path for the test in order to test specific paper paths. ALL TRAYS TRAY 1 TRAY 2* Specifies whether the test page is printed from all trays or from a specific tray. TRAY 3 TRAY 4 TRAY 5 OFF ON Determines whether the duplexer is included in the test. NOTE: This option is available only for models that have an automatic duplexer. 1* Determines how many pages should be sent from the specified 10 source as part of the test. 50 100 500 Performs tests to determine whether the paper path sensors are operating correctly. Performs additional tests to determine whether the paper path sensors are operating correctly. Activate individual parts independently to isolate noise, leaking, and other hardware issues. Range is 0 - 60,000 milliseconds. The default is 0. Isolates print quality faults more accurately by stopping the product in mid-print cycle, which allows you to see where the image begins to degrade. This causes a jam message that might need to be manually cleared. A service representative should perform this test. ENWW Control panel menus 41