Brother International BAS-375E Instruction Manual - English - Page 41

Adjusting the needle bar height, 3. Adjusting the needle clearance

|

View all Brother International BAS-375E manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 41 highlights

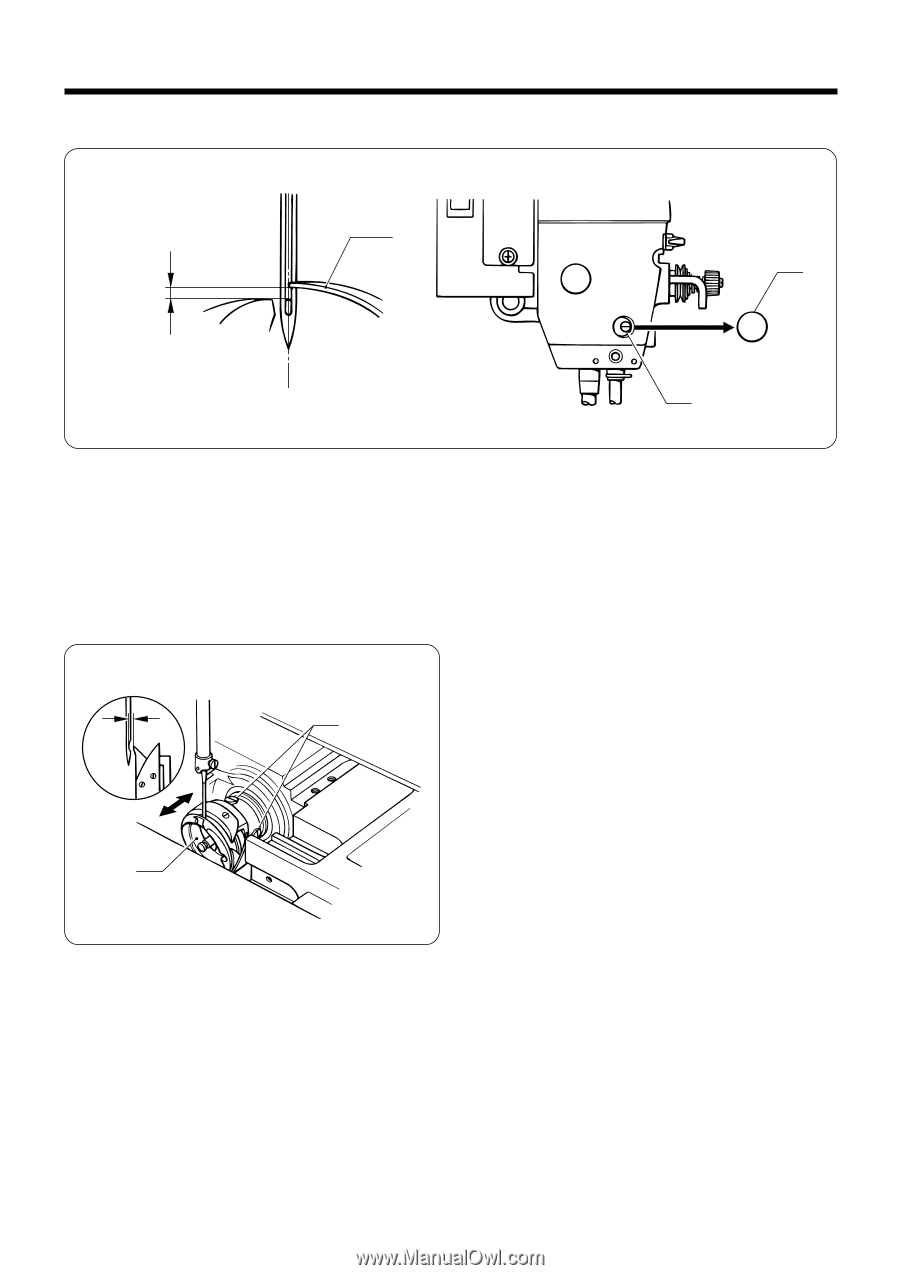

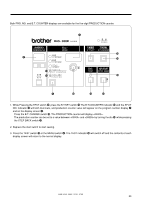

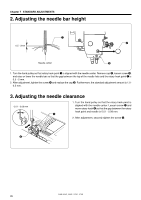

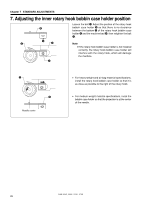

Chapter 7 STANDARD ADJUSTMENTS 2. Adjusting the needle bar height q w 0.5 - 2mm Needle center e 1. Turn the hand pulley so that rotary hook point q is aligned with the needle center. Remove cap w, loosen screw e, and raise or lower the needle bar so that the gap between the top of the needle hole and the rotary hook point q is 0.5 - 2 mm. 2. After adjustment, tighten the screw e and replace the cap w. Furthermore, the standard adjustment amount is 1.50.3 mm. 3. Adjusting the needle clearance 0.01 - 0.08 mm 1. Turn the hand pulley so that the rotary hook point is aligned with the needle center. Loosen screw q and move rotary hook w so that the gap between the rotary hook point and needle is 0.01 - 0.08 mm. q 2. After adjustment, securely tighten the screw q. w BAS-364E, 366E, 370E, 375E 35