Brother International BAS-375E Instruction Manual - English - Page 6

Contents

|

View all Brother International BAS-375E manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 6 highlights

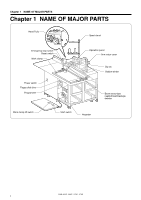

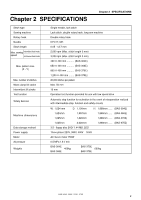

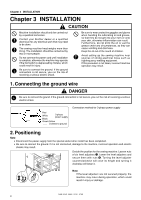

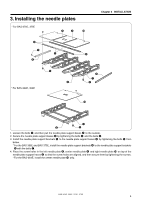

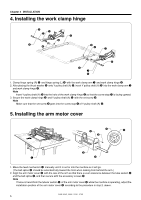

Contents Chapter 1 NAME OF MAJOR PARTS .... 1 Chapter 2 SPECIFICATIONS 2 Chapter 3 INSTALLATION 3 1. Connecting the ground wire 3 2. Positioning 3 3. Installing the needle plates 4 4. Installing the work clamp hinge 5 5. Installing the arm motor cover 5 6. Installing the foot switch 6 7. Installing the programmer box 6 8. Installing the programmer 6 9. Installing the spool stand 7 10. Preparation of cassette 7 11. Lubrication 8 12. Draining oil 9 13. Applying grease 10 14. Adjusting the air pressure 11 Chapter 4 CORRECT OPERATION ... 12 1. Turning the pulley by hand 12 2. Installing the needle 12 3. Threading the upper thread 13 4. Winding the lower thread 14 5. Installing the bobbin case 15 6. Thread tension 16 7. Work clamp 17 8. Selecting Intermittent feed or continuous feed ...... 18 Chapter 5 OPERATING PROCEDURE... 19 1. Part names and functions of the operation panel .. 19 2. Using the floppy disk 21 3. Using the program R/W (Read/Write) switch ........ 23 4. Using the emergency stop switch 24 5. Adjusting the sewing speed control 25 6. Changing the X-scale and Y-scale settings..... 25 7. Using the TEST switch (Checking the sewing pattern 26 8. Using the STEP BACK switch 27 9. Using single split mode 28 10. Using the bobbin thread counter 29 11. Using production counter 30 12. Shifting a stitch pattern 31 Chapter 6 Sewing 32 1. Before starting sewing 32 2. Sewing operation 33 Chapter 7 STANDARD ADJUSTMENTS .... 34 1. Needle and rotary hook timing 34 2. Adjusting the needle bar height 35 3. Adjusting the needle clearance 35 4. Adjusting the presser foot 36 5. Changing the presser foot lift amount ...... 37 6. Replacing the fixed knife and movable knife ..... 38 7. Adjusting the inner rotary hook bobbin case holder position 39 8. Checking the input voltage 40 9. Clearing all memory settings 40 Chapter 8 DEVICES 41 1. Needle thread presser 41 2. Beam sensor-type needle thread breakage detecor 41 3. Two-stage thread tension mechanism ..... 42 4. Stepping foot control mechanism 42 5. Needle cooler 43 6. Installing the bottom plunger 43 7. Jig pattern sensor 44 8. Sub clamp (BAS-370E, 375E only 45 Chapter 9 CLEANING AND INSPECTION ... 47 1. Rotary hook 47 2. Eye guard 47 3. Checking the needle 48 Chapter 10 DIP SWITCH 49 1. Panel DIP switch functions 49 2. DIP switches inside the control box .......... 50 Chapter 11 CHANGING SPECIAL FUNCTIONS USING AND THE MEMORY SWITCHES ..... 52 Chapter 12 ERROR CODE 57 Chapter 13 TROUBLESHOOTING ... 59 OPERATION FLOW CHART 61