Brother International BAS-375E Instruction Manual - English - Page 66

Check and remedy, lengths while referring to Thread tension.

|

View all Brother International BAS-375E manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 66 highlights

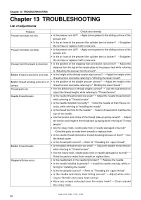

Chapter 13 TROUBLESHOOTING Problem Needle breaks. Check and remedy G Is the needle touching the rotary hook? / Adjust while referring to "Needle and rotary hook timing" and "Adjusting the needle clearance". G Is the needle bent or the needle tip broken? / Replace the needle. G Is the needle installed incorrectly? / Install the needle correctly, while re- ferring to "Installing the needle". G Is needle deflection occurring? / Select a needle which matches the ma- terial being sewn, or reduce the sewing speed. G Is the needle too thin? / Select a needle which matches the material being sewn. Needle thread is not trimmed. G Is the thread trimming timing correct? / Change the thread trimming tim- ing. G Is the fixed knife blunt? / Sharpen the fixed knife or replace it with a new knife. G Is the movable knife picking up the needle thread? / Adjust while referring to " Needle and rotary hook timing ". G Is the tension of the sub-tension correct? / Turn the nut to adjust to a suitable tension. Thread is tangling. G Is the needle and rotary hook timing correct? / Adjust while referring to "Needle and rotary hook timing". Poor seam finish on underside of G Are the threads being separated correctly at the rotary hook holder posi- material. tion? / Adjust while referring to "Adjusting the inner rotary hook bobbin case holder position". G Are the thread lengths correct? / Use the sub-tension to adjust the thread Poor thread tightening. lengths while referring to "Thread tension". G Is the needle thread tension too weak? / Adjust the needle thread tension while referring to "Thread tension". G Is the bobbin thread tension too weak? / Adjust the bobbin thread tension while referring to "Thread tension". Needle thread lengths are uneven. G Is the tension of the sub-tension correct? / Adjust the sub-tension while referring to "Thread tension". G Is the fixed knife correct? / Sharpen the fixed knife or replace it with a new knife. BAS-364E, 366E, 370E, 375E 60