Brother International BAS-375E Instruction Manual - English - Page 65

Troubleshooting

|

View all Brother International BAS-375E manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 65 highlights

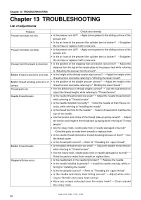

Chapter 13 TROUBLESHOOTING Chapter 13 TROUBLESHOOTING List of adjustments Problem Check and remedy Presser foot does not rise. G Is the presser arm stiff? / Apply some grease to the sliding surface of the presser arm. G Is the air hose of the presser lifter cylinder bent or broken? / Straighten the air hose or replace it with a new one. Presser foot does not drop. G Is the presser arm stiff? / Apply some grease to the sliding surface of the presser arm. G Is the air hose of the presser lifter cylinder bent or broken? / Straighten the air hose or replace it with a new one. Presser foot lift amount is incorrect. G Is the position of the stepping foot connection rod correct? / Adjust the distance from the top of the needle plate to the presser foot while referring to "Adjusting the presser foot lift amount". Bobbin thread is wound to one side. G Is the height of the thread tension stud correct? / Adjust the height of the thread tension stud while referring to "Winding the lower thread". Bobbin thread winding amount is in- G Is the position of the bobbin presser correct? / Adjust the height of the correct. Thread pulls out. thread tension stud while referring to " Winding the lower thread ". G Are the differences in thread lengths correct? / Use the sub-tension to adjust the thread lengths while referring to "Thread tension". Needle thread breaks. G Is the needle thread tension too weak? / Adjust the needle thread tension while referring to "Thread tension". G Is the needle installed incorrectly? / Install the needle so that it faces cor- rectly, while referring to "Installing the needle". G Is the thread too thick for the needle? / Select a thread which matches the size of the needle. G Are the tension and stroke of the thread take-up spring correct? / Adjust the tension and height of the thread take-up spring while referring to "Thread tension". G Are the rotary hook, needle plate hole or needle damaged or burred? /Grind the parts to make them smooth or replace them. G Is the needle thread (decorative thread) breaking because of heat? / Use the thread cooler. G Is the thread path correct? / Refer to "Threading the upper thread". Bobbin thread breaks. G Is the bobbin thread tension too weak? / Adjust the bobbin thread tension while referring to "Thread tension". G Are the rotary hook, needle plate hole or needle damaged or burred? / Grind the parts to make them smooth or replace them. Skipped stitches occur. G Is the needle bent or the needle tip broken? / Replace the needle. G Is the needle installed incorrectly? / Install the needle correctly, while re- ferring to "Installing the needle". G Is the thread path correct? / Refer to "Threading the upper thread". G Is the needle and rotary hook timing correct? / Adjust while refer- ring to "Needle and rotary hook timing". G Have any scraps collected near the rotary hook?/ Clean around the rotary hook. BAS-364E, 366E, 370E, 375E 59