IBM 25R0012 User Guide - Page 73

Broken, Mid-tape

|

UPC - 000435800176

View all IBM 25R0012 manuals

Add to My Manuals

Save this manual to your list of manuals |

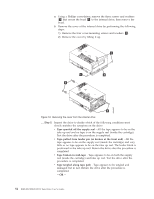

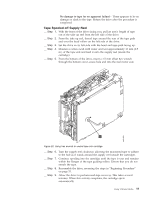

Page 73 highlights

__ Step 4. As the LBA is secured in the cartridge, you should hear the LBA retention spring clips click into place. If you do not hear the click, continue rolling until the threader motor worm gear 4 stops. The LBA is in the correct position. Note: Be sure to keep tension on the tape as the LBA is drawn into the cartridge by using a hex wrench as shown in the figure above. __ Step 5. Notice the following: a. Loader mechanism gear 8 nearest the front of the drive that actuates the cartridge loader mechanism b. Position of the rotator stub 3 . c. Front loader motor worm gear 1 . Rotating this gear allows the loader mechanism gear 8 to turn. __ Step 6. Rotate the loader motor worm gear 1 to turn the loader mechanism gear 6 counterclockwise. Continue turning until the rotator stub 3 loses contact with the lever 7 . This releases the LBA leader pin. __ Step 7. Rotate the threader motor worm gear 4 to turn the threader mechanism gear 6 counterclockwise. This moves the LBA out of the cartridge and past the read/write head. Stop this rotation when the LBA is near the tape guide roller nearest the rear of the drive 1 . 1 Figure 22. Leader Block Assembly (LBA) __ Step 8. Continue rotating the loader motor worm gear 1 until the rotate stub 3 is positioned as shown. Notice that the rotator stub 3 is nearly aligned with the cartridge loader tray guide bearing 2 . __ Step 9. Remove the cartridge from the cartridge loader tray. __ Step 10. Reassemble the drive by reversing the procedure in Step 4 in "Beginning Procedure" on page 53. __ Step 11. Refer to the appropriate procedure to install the new drive and return the failed drive. Tape Broken in Mid-tape __ Step 1. With the front of the drive facing you, pull an arm's length of tape out of the take up reel from the left side of the drive. Note: If there is less than approximately 5 cm (2 in.) of tape on the take up reel, go to "Tape Pulled from or Broken near Leader Pin" on page 56. Using Ultrium Media 57 a82ru010