Konica Minolta C83hc High Chroma AccurioPress C6100/C6085 AccurioPress C3080/C - Page 70

Troubleshooting, 8.1 If an Out-of-Range Image is Detected

|

View all Konica Minolta C83hc High Chroma manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 70 highlights

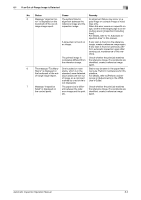

8.1 If an Out-of-Range Image is Detected 8 8 Troubleshooting 8.1 If an Out-of-Range Image is Detected Out-of-range image report status and remedy When message "Out of range was detected." is displayed on the touch panel, check the out-of-range image report. No. Status Cause Remedy 1 A comment marked by a Out-of-range stains were Stains may be seen in the paper feed- red circle is displayed on detected. ing route. Perform maintenance for this the out-of-range image machine. report, and also stains For details, refer to [Adjustments] or are found on the actual [Machine Management] in the HTML printouts. User's Guide. 2 A comment marked by a The inspection accuracy Lower one of the following levels. red circle was displayed level may be too high. • Inspection Level on the out-of-range im- • [Detection Level] age report, but no stains • [Paper Noise Removal Level] are found on the actual printouts. The paper of the reference image and the ac- Load the paper that is used to create a reference image. tual printout is different. Otherwise, load the paper you want to actually use, and create a reference im- age again. The scanner unit of the Intelligent Quality Optimizer IQ-501 is dirty. Clean the scanner unit. For details, refer to [Machine Management] ) [Cleaning] ) [Cleaning Intelligent Quality Optimizer IQ-501] or [Cleaning Quality Optimizer IQ-501] in the HTML User's Guide. 3 An error occurs in the The original data is erro- Check the inspection data and decod- barcode inspection or neous. ing results (CSV file in the report). serial No. (0-9) inspec- Or, the setting does not Also, check whether the barcode area tion area. match the specifications. or serial No. (0-9) area is set based on the specifications. For details, refer to "6. Automatic In- spection Area" in this manual. 4 A comment marked by a A stain was detected on Perform maintenance for this machine, pink circle is displayed the reference image, or and create a reference image again. on the out-of-range im- an out-of-range image Otherwise, lower the [Inspection Level]. age report. omission was detected. Automatic Inspection Operation Manual 8-2