Toro 20330 Service Manual - Page 112

engage the flywheel. If you do not have an

|

UPC - 021038203300

View all Toro 20330 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 112 highlights

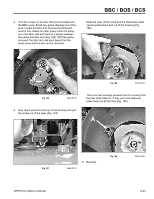

BBC / BOS / BCS They are noise dampeners. Without them, when the brake pad hits the drum, the drum will ring like a bell. Also look at the two blade mounting bolts. Each has a flat side on the head to prevent them from rotating when the nut is tightened (Fig. 196). Make sure the bolts are fully seated. Install the brake drum. CAUTION! The two bumps on the pulley MUST engage the flywheel. If you do not have an impact wrench, this is where the two bumps become important. If you engage the bumps on the pulley into the flywheel, you can now wedge the flywheel and through the pulley and key, it will hold the crankshaft from rotating while you tighten the nut (Fig. 197). Fig 196 3428-0189 4. Inspect the hub assembly if the old one is to be reused. Rust on the outside is harmless. But the seals in the bearing need to be intact. If the seals are damaged or the bearing feels rough when it is turned, replace the hub assembly. 5. Start the nut on the crankshaft. As during disassembly, an impact wrench works best. Fig 197 3428-0187 6. Slip the BBC belt over the parts on the crankshaft. 7. Check the shaft of the idler/brake arm. Clean as necessary and apply a light coat of grease. 6-26 WPM Drive Systems Manual