Brother International BES-116 Instruction Manual - English - Page 129

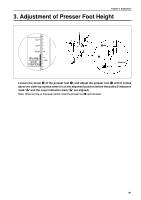

of the top dead center stopper

|

View all Brother International BES-116 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 129 highlights

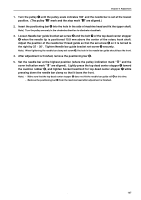

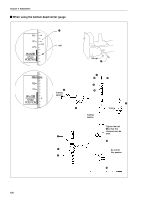

Chapter 8 Adjustment 1. Turn the pulley q until the pulley scale indicates 180° and the needle bar is set at the lowest position. (The pulley " " mark and the stop mark " " are aligned.) 2. Insert the positioning bar w into the hole in the side of machine head and fix the upper shaft. Note) Turn the pulley securely in the clockwise direction to eliminate a backlash. 3. Loosen Needle bar guide bracket set screw e and the bolt u of the top dead center stopper t when the needle tip is positioned 10.8 mm above the center of the rotary hook shaft. Adjust the position of the needle bar thread guide so that the set screw r on it is turned to the right by 25 ~ 30°. Tighten Needle bar guide bracket set screw e securely. Note) When tightening the needle bar clamp set screw e, the hole in the needle bar guide should face the front. 4. After adjustment is finished, remove the positioning bar w. 5. Set the needle bar at the highest position (where the pulley indication mark " " and the cover indication mark " " are aligned). Lightly press the top dead center stopper t toward the cushion rubber y, and tighten Socket head bolt for top dead center stopper u while pressing down the needle bar clamp so that it faces the front. Note) • Make sure that the top dead center stopper t does not hit the needle bar guide rail i at this time. • Remove the positioning bar w from the machine head after adjustment is finished. BES-116AC 127