HP 2100 Service Manual - Page 43

Envelopes with Adhesive Strips or Flaps, Envelope Storage, Table 2-4. Envelope Specifications - ink

|

UPC - 873662008284

View all HP 2100 manuals

Add to My Manuals

Save this manual to your list of manuals |

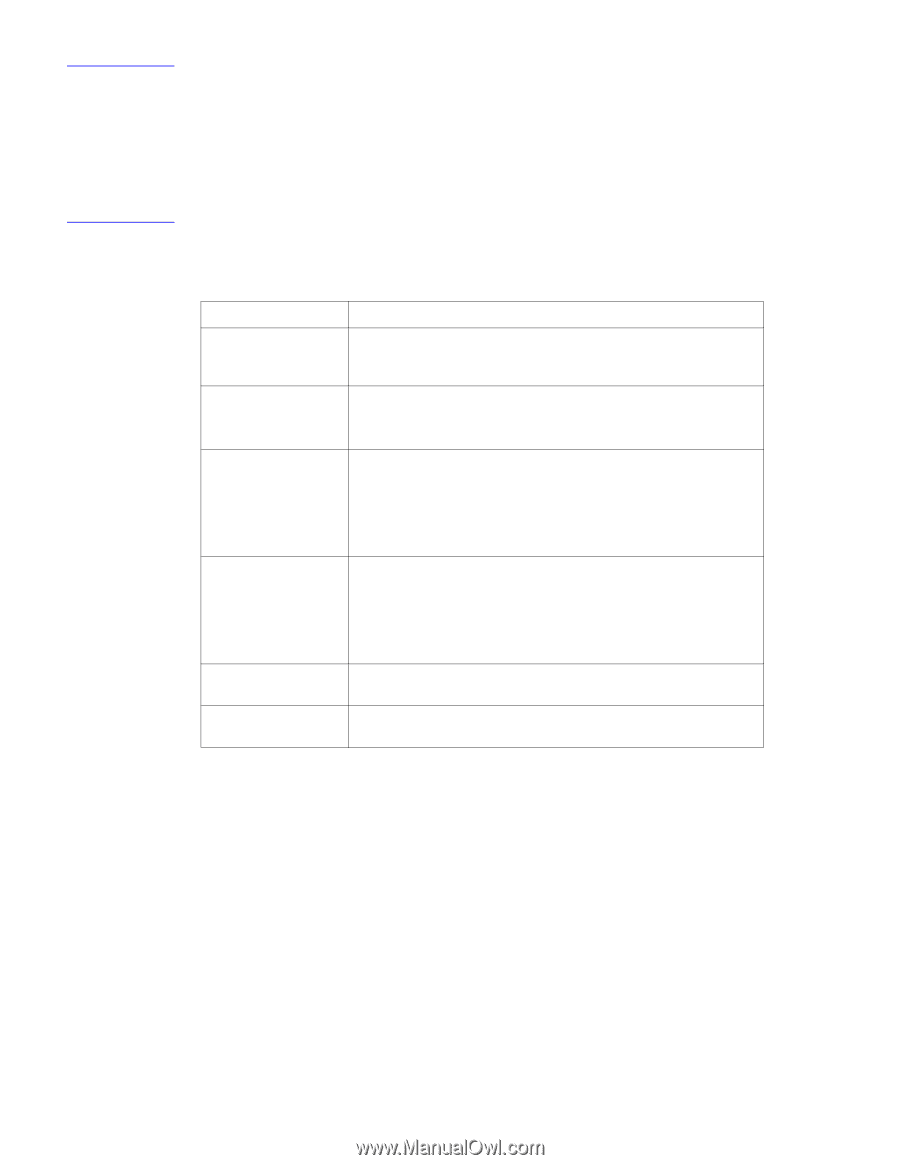

Page 43 highlights

NOTE: Use only Tray 1 to print envelopes. Some paper jams might occur when using any media with a length less than 178 mm (7 in.). This might be caused by paper that has been affected by environmental conditions. Envelopes might meet the general specifications listed in table 2-4 and still not print satisfactorily because of the printing environment or other variables over which HP has no control. Table 2-4. Envelope Specifications Description Paper Basis Weight Finish Fusing Compatibility Curl (Pre-Printed) Caliper Specification Paper used for envelope construction must meet the paper specifications listed in this manual and the HP LaserJet Printer Paper Specifications Guide (except for those listed below). 16 to 27# (60 to 100 g/m2), single thickness. Jamming might result if 27# (100 g/m2) is exceeded. See "Basis Weight Field Test" (page 38). Avoid using envelopes with adhesive exposed to the printer. Envelopes must be folded accurately (+/- 0.04 inch) so that there are no more than two thicknesses of paper anywhere along the leading edge. All folds must be well scored and sharply creased, and construction must be tight (not baggy). Avoid using envelopes that are stuck together with excess seam gum. All inks, adhesives, and other materials used in the envelope must be compatible with the heat and pressure of the fusing process. Materials must not discolor, melt, offset, or release hazardous emissions when heated to 200 degrees Celsius (392 degrees Fahrenheit) for 0.1 second. See "Fusing Compatibility Field Test" (page 42). Envelopes must lie flat, with no more than 5 mm (0.2 inch) curl across the entire surface. See "Curl Field Test" (page 41). 0.084 to 0.14 mm (3.3 to 5.5 mils), single thickness. See "Caliper Field Test" (page 39). Envelopes with Adhesive Strips or Flaps Envelopes with a peel-off adhesive strip or with more than one flap that folds over to seal must use adhesives compatible with the heat and pressure in the printer. The extra flaps and strips might cause wrinkling, creasing, or jams and may even damage the fuser. Envelope Storage Proper storage of envelopes contributes to print quality. Envelopes should be stored flat. If air is trapped in an envelope, creating an air bubble, then the envelope may wrinkle during printing. C4170-90959 Media Specifications 33