HP 2100 Service Manual - Page 46

Transparency Specifications, Storing Print Media, Description, Specification - abl

|

UPC - 873662008284

View all HP 2100 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 46 highlights

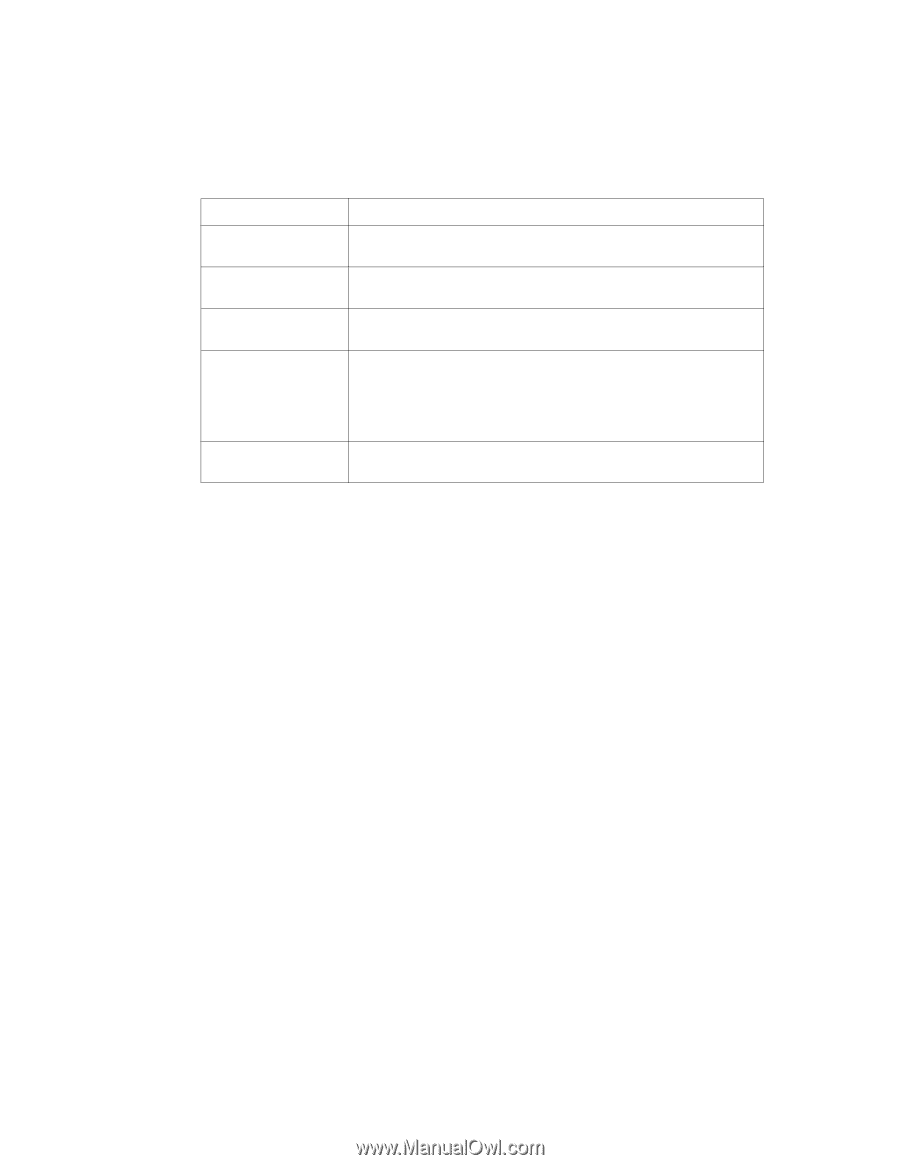

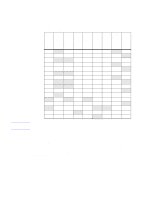

Transparency Specifications Transparencies used in the printer must be able to withstand 200 degrees C (392 degrees F), the printer's fusing temperature. To avoid damaging the printer, use only transparencies recommended for use in laser printers, such as HP-brand transparencies, and print transparencies to the top output bin. Table 2-7. Transparency Specifications Description Surface Resistivity Volume Resistivity Finishing Precision Fusing Compatibility Caliper Specification 2.0 to 15 X 10 to the 10th ohm square. See "Tools and Suppliers" (page 42). 1.2 to 15 X 10 to the 11th ohm-centimeter. See "Tools and Suppliers" (page 42). Cut sheet within 0.79 millimeters (0.031 inches) of nominal and +0.20 degrees square. Transparency materials must be compatible with the heat and pressure of the fusing process. Materials must not discolor, melt, offset, or release hazardous emissions when heated to 200 degrees Celsius (392 degrees Fahrenheit) for 0.1 second. See "Fusing Compatibility Field Test" (page 42). 0.100 to 0.110 mm (3.9 to 4.3 mils). See "Caliper Field Test" (page 39). Storing Print Media Ideally, the printing and paper storage environment should be at or near room temperature, and not too dry or too humid. Remember paper is hygroscopic; it absorbs and loses moisture rapidly. Heat works with humidity to damage paper. Heat causes the moisture in paper to evaporate, while cold causes it to condense on the sheets. Heating systems and air conditioners remove most of the humidity from a room. As a paper package is opened and used, it loses moisture, causing streaks and smudging. Humid weather or water coolers can cause the humidity to increase in a room. As paper is opened and used it absorbs any excess moisture, causing light print and dropouts. Also, as paper loses and gains moisture it can distort. This can cause paper jams. As a result, paper storage and handling are as important as the paper-making process itself. Paper storage environmental conditions directly affect the feed operation. Users should not purchase more paper than can be easily used in a short time (about 3 months). Paper stored for long periods may experience heat and moisture extremes, which can cause damage. Planning is important to prevent damage to a large supply of paper. Unopened paper in sealed reams can remain stable for several months before use. Opened packages of paper have more potential for environmental damage, especially if they are not wrapped with a moisture-proof barrier. 36 Chapter 2 Operating Requirements C4170-90959