HP LaserJet Pro CP1525 Service Manual - Page 95

Print-quality troubleshooting tools, Repetitive image defects

|

View all HP LaserJet Pro CP1525 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 95 highlights

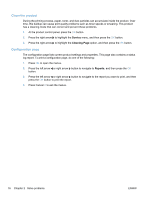

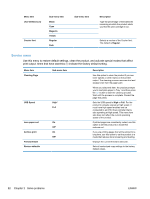

Print-quality troubleshooting tools Repetitive image defects If the product output has a consistent, repetitive defect, use the table in this section to determine which part needs to be replaced based on the measured distance between the repetitions of the defect. Repetitive defects for the ITB normally appear on every other page, because the ITB is longer than a page. However, the period of the repetitive defect can vary depending on the type of media, and a repetitive defect can occur more than once on the same page. NOTE: The following table replaces the graphical repetitive defect ruler. You can make your own ruler by using these measurements. Table 2-2 Repetitive image defects Distance between identical defects Component Notes 22.3 mm (0.87 in) Developer roller (one rotation) Appears in a single color plane 26.7 mm (1.05 in) 28.5 mm (1.12 in) Charger roller Developer RS roller (one rotation) Appears in a single color plane. Inside developer, it and removes and supplies toner to the developer sleeve. 44.0 mm (1.73 in) Registration roller 56.5 mm (2.22 in) Fuser film (one rotation) Appears in all color planes. 56.8 mm (2.23 in) Fuser pressure roller (one rotation) Appears in all color planes. 57.0 mm (2.24 in) Transfer roller Appears in all color planes. 69.0 mm (2.71 in) Cartridge-to-cartridge spacing Distance between each color OPC. 75.8 mm (2.98 in) 633.6 mm (24.94 in) OPC drum (one rotation) ITB Appears in a single color plane and might be either a dark or white spot. Because the ITB is longer than a page, you might have to look at multiple pages to determine if a repetitive defect is present. 69.0 mm (2.71 in) ITB drive roller pitch Calibrate the product to align the colors If the printed output has colored shadows, blurry graphics, or areas that have poor color, you might need to calibrate the product to align the colors. Print the Diagnostics Page from the Reports menu on the control panel to check the color alignment. If the blocks of color on that page are not aligned with each other, you need to calibrate the product. 1. On the product control panel, open the System Setup menu. 2. Open the Print quality menu, and select the Calibrate color item. 3. Select the Calibrate now option. ENWW Tools for troubleshooting 77